Plain Steel Grating is a versatile solution for many construction projects. According to a report by Grand View Research, the global steel grating market is projected to grow significantly, reaching $4.2 billion by 2025. This growth reflects its increasing usage across various sectors, including industrial, commercial, and municipal applications.

The benefits of Plain Steel Grating are numerous. Its durability and strength make it ideal for heavy-load environments. In fact, many industries report lower maintenance costs when adopting this material. However, there are still challenges in proper installation and design that require careful consideration. Some projects may underestimate the impact of environmental factors on grating performance.

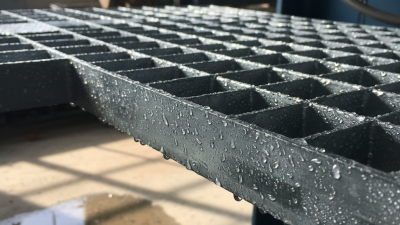

Moreover, Plain Steel Grating is prized for its slip-resistant surface, enhancing safety in workplaces. Yet, not all products on the market deliver the same level of reliability. Hence, selecting the right manufacturer and understanding the specific needs of a project are vital. This awareness can lead to better decisions, ensuring that the benefits outweigh the potential pitfalls of improper choices.

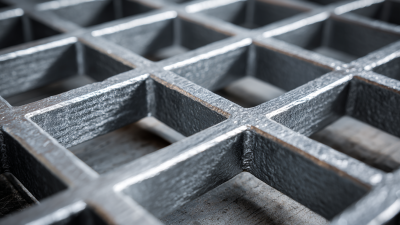

Plain steel grating offers impressive durability and strength, making it a preferred choice for various projects. Its robust design can withstand heavy loads and harsh environments. This type of grating holds up well against wear and tear. It can last for years with minimal maintenance, saving time and resources.

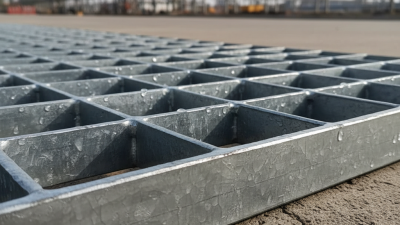

The strength of plain steel grating provides reliable support in industrial settings. It can handle high foot traffic, making it ideal for walkways and platforms. Whether in warehouses or factories, the stability it offers is crucial. However, it's essential to consider potential rusting if not properly treated. Rust can weaken the material over time, leading to safety concerns.

In terms of versatility, plain steel grating adapts to different applications. It can be customized to fit various sizes and shapes. However, the weight may be a downside for some projects. Lighter materials could be easier to handle, but they often lack the strength of steel. Therefore, weighing the pros and cons is vital for project success.

Plain steel grating is an essential material in construction projects. Its cost-effectiveness is a significant advantage. According to industry reports, using plain steel grating can reduce material costs by up to 30%. This reduction is crucial for tight budgets. Projects can save more while ensuring quality and performance.

When considering plain steel grating, think about installation time. Faster installation means lower labor costs. A study by the American Institute of Steel Construction shows that efficient building practices can result in savings of 15% on labor expenses. This adds to the overall budget advantages.

**Tips**: Always compare quotes from suppliers. Understand the weight load your project requires. Choose the right gauge to balance cost and strength. Remember, not all gratings are equal. Consider future maintenance costs too. A cheaper option today may become costly over time. Overall, the long-term benefits might outweigh initial savings.

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| Durability | Plain steel grating is resistant to wear and tear, ensuring long-lasting performance. | Reduced replacement costs due to longevity. |

| Versatility | Can be used in various applications, including walkways, platforms, and industrial flooring. | Lower investment as it serves multiple purposes. |

| Easy Installation | Lightweight and easy to handle, reducing labor costs during installation. | Saves on labor and equipment rental expenses. |

| Low Maintenance | Requires minimal upkeep, saving time and costs over its lifespan. | Fewer maintenance costs compared to other materials. |

| High Load Capacity | Strong enough to support heavy machinery and foot traffic. | Reduces the need for additional supports, lowering material costs. |

| Safety | Non-slip surface options available, enhancing safety for users. | Potential to lower liability insurance costs due to safer working environments. |

| Environmentally Friendly | Recyclable material reduces waste in landfills. | Can qualify for green building credits, potentially lowering project costs. |

| Aesthetic Flexibility | Available in various finishes and colors to match design needs. | Avoids additional costs for complementary materials. |

| Cost Effectiveness | Affordably priced compared to alternative materials. | Overall savings in budgeting for large projects. |

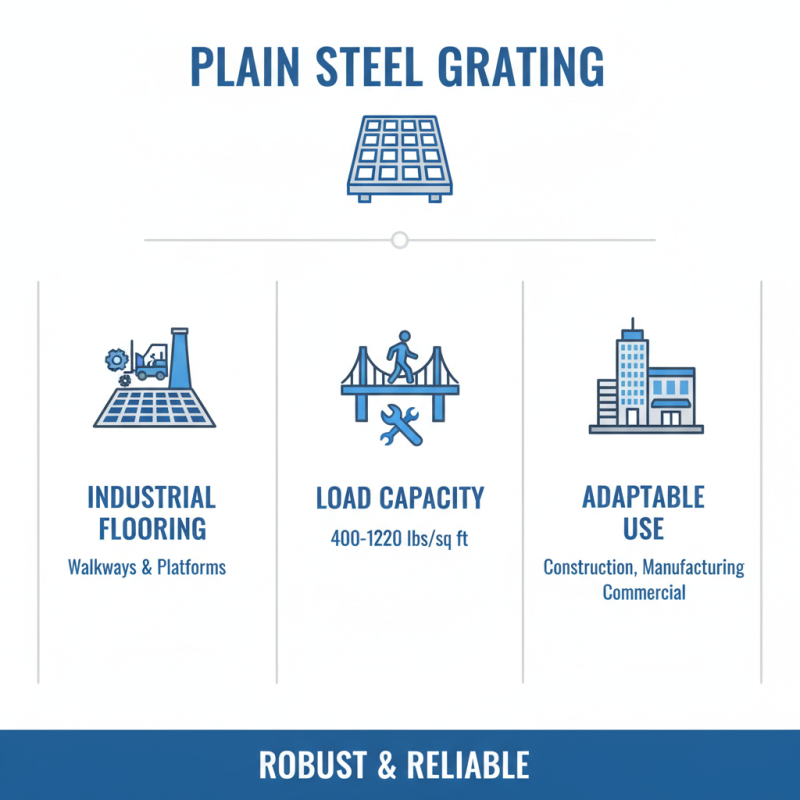

Plain steel grating offers remarkable versatility across various industries. Its robust design makes it ideal for floor systems, walkways, and platforms. With a load-bearing capacity that ranges from 400 to 1,200 pounds per square foot, it's suitable for heavy machinery and pedestrian traffic alike. This adaptability is crucial in construction, manufacturing, and commercial applications.

Additionally, the ease of customization is a significant advantage. Plain steel grating can be cut to fit unique dimensions, enhancing its functionality. According to industry reports, over 60% of professionals prefer using it due to its long lifespan and low maintenance needs. However, the susceptibility to rust can be a concern in corrosive environments. This drawback highlights the need for regular inspections and potential protective coatings.

In applications such as drainage systems and HVAC platforms, the non-slip surface of plain steel grating plays a critical role. This feature helps prevent accidents in busy industrial settings. Despite its strength, some users notice that installation can be labor-intensive. Balancing these challenges with its benefits is essential for optimal performance.

Plain steel grating offers significant maintenance and safety advantages. This material is known for its durability and strength. A study indicated that well-maintained steel grating can last over 25 years. Regular inspections help identify wear and tear. This proactive approach minimizes risks of unexpected failures.

Safety is paramount in any construction project. Plain steel grating provides excellent traction, reducing slip hazards. Reports show that areas with proper grating see a 30% decrease in accidents. Additionally, the open design allows for quick drainage, minimizing water buildup. However, periodic upkeep is essential to maintain these benefits. Neglecting maintenance can lead to corrosion, which affects safety.

Some projects overlook the long-term advantages of plain steel grating. Initial costs might seem high, but this material saves money on replacements. Many decision-makers fail to recognize the total lifecycle costs. Investing in quality steel grating pays off in reduced injuries and lower maintenance expenses. Each project should critically assess its needs. Embracing steel grating can enhance both safety and efficiency.

Plain steel grating offers a unique aesthetic appeal that enhances any project. Its industrial look can add character to modern architecture. The versatility of plain steel grating allows it to be used both indoors and outdoors. You can find it in walkways, platforms, or even as wall features. The clean lines and simple design let it blend seamlessly with various styles.

Design flexibility is another significant benefit of plain steel grating. It can easily be customized to fit specific dimensions and shapes. Whether you need a long span or intricate designs, it caters to diverse project needs. The ease of installation makes it appealing to many builders. However, some might feel it lacks warmth compared to other materials. In certain applications, it may come off as too harsh or cold. Balancing its industrial charm with softer elements can create a harmonious environment.