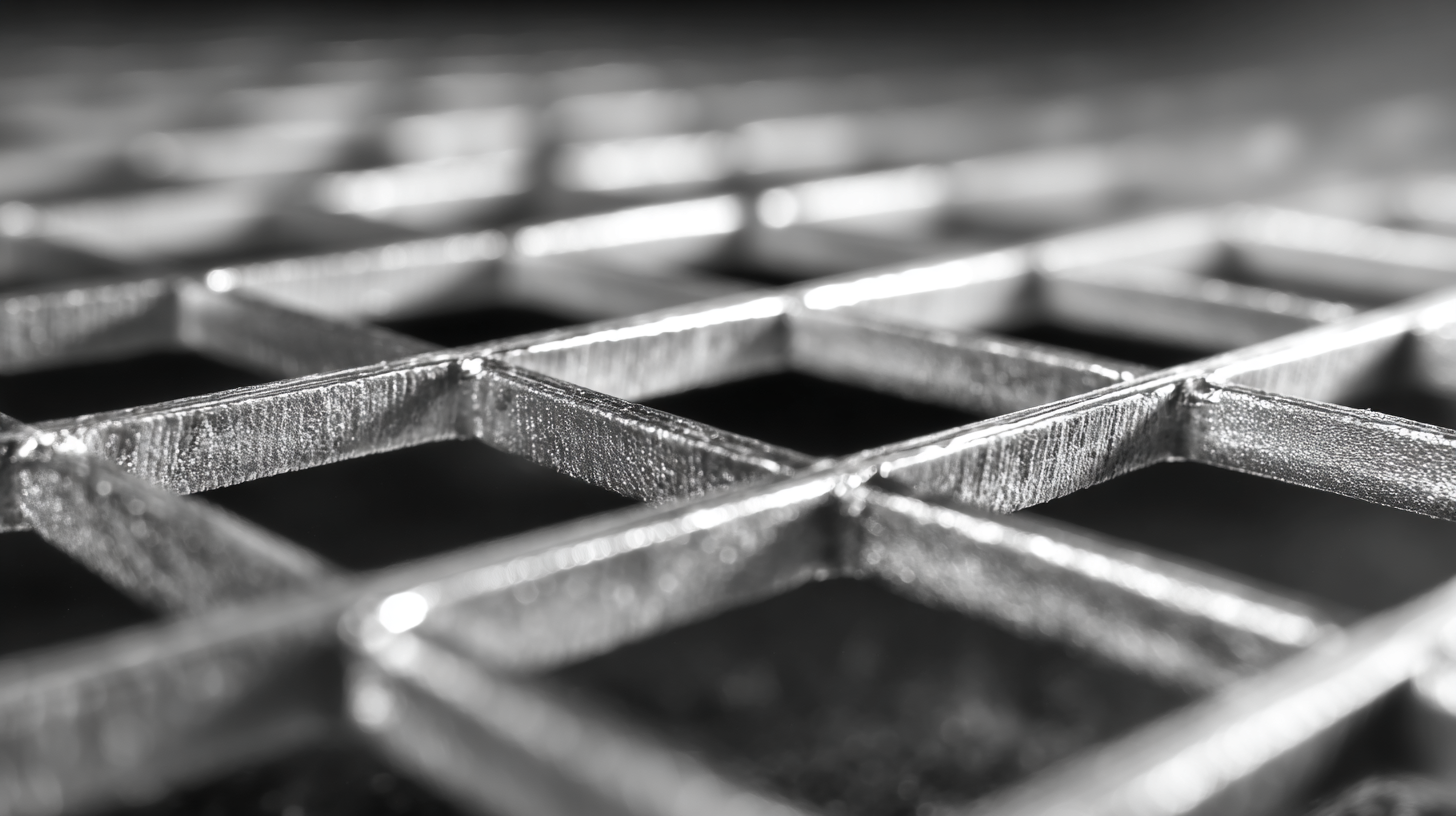

The construction industry has increasingly recognized the advantages of using Mill Finish Steel Grating, a versatile and durable material that meets the demands of modern building practices. According to a report by MarketsandMarkets, the global steel grating market is expected to reach USD 1.8 billion by 2025, reflecting a growing preference for high-performance materials like Mill Finish Steel Grating that offer strength and longevity. This type of grating not only provides exceptional load-bearing capacity but also enhances aesthetics and safety in various applications, from pedestrian walkways to industrial facilities. Furthermore, a study by Grand View Research indicates that the rising investments in infrastructure development worldwide are driving the demand for advanced construction materials, further solidifying the role of Mill Finish Steel Grating in optimizing both functional and design aspects of construction projects.

Mill finish steel grating offers unique properties that make it a valuable choice in modern construction projects. One of its standout features is its durability. Made from high-quality steel, this type of grating provides a strong and reliable surface that can withstand heavy loads and harsh environmental conditions. This strength is essential in various applications, from industrial flooring to municipal projects, where safety and longevity are paramount.

In addition to its structural integrity, mill finish steel grating possesses a non-slip surface, making it safe for use in areas with high foot traffic or potential exposure to liquids. This characteristic reduces the risk of accidents, ensuring that the spaces where it is installed remain secure for workers and visitors alike. Moreover, the natural finish of the steel offers a sleek, industrial aesthetic that can complement a wide range of architectural designs, enriching both functionality and visual appeal in contemporary construction.

Mill finish steel grating offers numerous advantages that contribute significantly to structural integrity in modern construction. One of the primary benefits is its high strength-to-weight ratio, which provides excellent load-bearing capabilities without adding unnecessary bulk to structures. This characteristic makes it an ideal choice for applications such as walkways, platforms, and stairs, where safety and robustness are crucial. The durability of mill finish steel grating also ensures that it can withstand heavy foot traffic and harsh environmental conditions, reducing the need for frequent replacements.

Another advantage of using mill finish steel grating is its resistance to corrosion, particularly when a proper coating or treatment is applied. This property enhances the longevity of the grating, ensuring that it retains its structural integrity over time and minimizes maintenance costs for building owners. Additionally, the open design of steel grating facilitates efficient drainage and airflow, preventing water accumulation and protecting the structural components from potential damage. These features collectively make mill finish steel grating a prevalent choice in contemporary construction, where reliability and safety cannot be compromised.

| Benefit | Description | Impact on Construction |

|---|---|---|

| Durability | Resistant to corrosion and harsh weather conditions. | Longer lifespan reduces the need for frequent replacements. |

| Low Maintenance | Minimal upkeep required compared to other materials. | Decreases overall maintenance costs for projects. |

| Weight Efficiency | Lightweight compared to solid flooring solutions. | Easier handling and installation, saving time and labor costs. |

| Non-slip Surface | Textured surface ensures safety in wet or slippery conditions. | Enhances safety for workers and reduces liability risks. |

| Versatility | Can be used in various applications, including flooring and walkways. | Adaptable in diverse environments, maximizing project flexibility. |

Mill finish steel grating has emerged as a cost-effective solution in modern construction projects. According to a recent report from the American Institute of Steel Construction (AISC), utilizing mill finish steel grating can result in savings of up to 30% compared to traditionally coated alternatives. This significant reduction in costs is attributed to the lower initial expenditure associated with mill finish steel, which requires less processing and finishing. As a result, builders can allocate their budgets more effectively, investing in other critical areas of their projects.

Furthermore, the durability and maintenance aspects of mill finish steel grating contribute to its cost-effectiveness. A study published by the Steel Network indicates that mill finish grating has a longer lifespan, with corrosion resistance not leading to frequent replacements. With average maintenance costs estimated at 50% less than those for painted or coated products, the long-term financial benefits become increasingly evident. This combination of lower upfront costs and reduced maintenance expenses positions mill finish steel grating as a viable option for contractors focusing on budget constraints while delivering quality construction results.

Mill finish steel grating is gaining popularity in modern construction, not only for its strength and durability but also for its environmental benefits. This product, made from recycled materials, contributes to sustainable building practices, reducing the need for new resources. By choosing mill finish steel grating, construction projects can minimize their carbon footprint, as the manufacturing process consumes less energy compared to other finishes. Moreover, mill finish steel is fully recyclable at the end of its life cycle, making it an excellent choice for environmentally conscious builders.

Tip: When selecting materials for your next project, consider those that minimize environmental impact. Opting for products like mill finish steel grating not only supports sustainability but can also enhance the overall aesthetic of your design.

Additionally, mill finish steel grating offers longevity, reducing waste and the need for frequent replacements. The inherent resistance to corrosion means that it can withstand harsh conditions without the need for harmful coatings or treatments, further contributing to a healthier environment. By using materials that last longer, the construction industry can better support eco-friendly practices while providing high-performance solutions.

Tip: Always check for the recycled content in materials to ensure that you are making a responsible choice for a greener future.

In modern architecture and design, mill finish steel grating has emerged as a versatile and efficient solution for various applications. Its lightweight yet strong construction makes it ideal for walkways, platforms, and other structural elements that require durability without sacrificing aesthetics. The open design allows for natural light and ventilation, enhancing the ambiance of any space, whether it be residential or commercial.

One of the significant advantages of using mill finish steel grating is its resistance to corrosion, making it suitable for outdoor settings and environments exposed to moisture. Additionally, its sustainable manufacturing process aligns with the growing emphasis on eco-friendly design in modern construction. Architects and designers appreciate the material's ease of installation and maintenance, providing both cost-effectiveness and longevity to projects.

**Tip:** When considering mill finish steel grating for your design, think about pairing it with other materials for contrast. This can create visual interest and depth in your architectural projects. Also, exploring the integration of smart technology with structural elements can further enhance functionality and sustainability in modern buildings.