In the construction and manufacturing sectors, "Mill Finish Steel Grating" is gaining attention. Industry expert John Smith, known for his insights on materials, states, “Mill Finish Steel Grating offers durability and cost-efficiency.” This material is often overlooked, despite its significant advantages.

One clear benefit is its strength. Mill Finish Steel Grating can withstand heavy loads, making it ideal for various projects. Its resistance to corrosion adds to its longevity, reducing the need for replacements. The finish also gives it a unique aesthetic appeal that can blend with different designs.

However, not every project may be suitable. Some might require more refined finishes or additional treatments. As with any material, understanding the specific needs of your project is essential. Mill Finish Steel Grating holds promise, but careful consideration must be given to its application.

Mill finish steel grating offers a range of advantages that set it apart from other materials. One of the most significant benefits is its superior corrosion resistance. A study from the American Institute of Steel Construction reveals that steel grating treated with a mill finish has a lifespan that is 25% longer than untreated options. This feature is particularly important in environments exposed to harsh weather or chemicals.

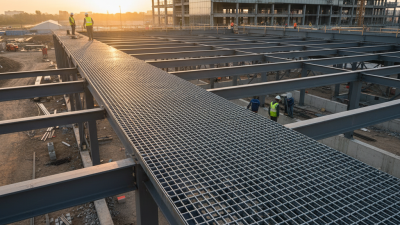

In addition to its durability, mill finish steel grating is notably versatile. It is used in various applications, from walkways to industrial platforms. A report from the Steel Sustainability Forum highlights that using steel grating can reduce weight by up to 35% compared to other flooring options. This reduction in weight not only eases installation but also lowers transportation costs, making it an economical choice.

However, it’s essential to consider the aesthetics of mill finish steel grating. While functional, its raw appearance may not suit all projects, leading to potential design challenges. Some projects may require additional finishes for visual appeal, adding complexity to procurement processes. Yet, its cost-effectiveness and durability often outweigh these concerns, making it a practical option for many engineers and project managers.

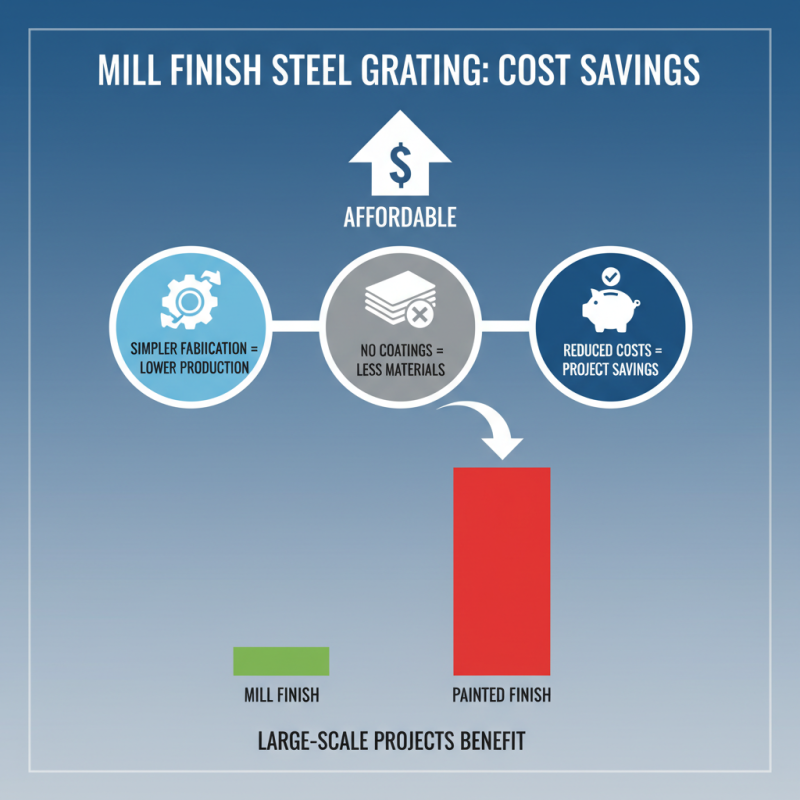

Mill finish steel grating offers significant cost savings, especially for large-scale projects. Its fabrication process is simpler than that of painted finishes, leading to lower production costs. This type of grating is manufactured without additional coatings, which means fewer materials are used. Consequently, the final product remains affordable while meeting structural requirements.

Projects involving extensive foot traffic or heavy machinery can benefit greatly from mill finish options. Durability and ease of installation make it attractive. Workers often find it less cumbersome to handle and install. However, some may question whether the bare finish is sufficient for their specific needs. Mill finish steel grating may corrode faster in harsh environments, which could lead to long-term concerns.

Another aspect to consider is maintenance. Mill finish steel grating typically requires more frequent inspections and cleaning. While this can be perceived as a drawback, it also prompts proactive project management. Ensuring regular upkeep prevents costly repairs in the future. Overall, mill finish steel grating presents a balanced choice, combining cost-effectiveness with practical considerations for large projects.

Mill finish steel grating offers exceptional durability, making it ideal for harsh environments. Its carbon steel composition provides a solid foundation. This type of grating resists corrosion and can endure extreme temperatures. These factors are essential for projects exposed to weathering elements.

When dealing with heavy loads, mill finish steel grating doesn't buckle easily. However, it’s crucial to install it properly. An improper installation can lead to uneven support and potential failure. Always check for any weak points during installation.

Tips for maintenance include regular inspections. Look for signs of wear or rust. If there's any damage, it’s better to address it early. Neglecting minor issues can lead to bigger problems down the line. Although mill finish steel grating is tough, it requires attention to stay in top condition.

Mill finish steel grating offers unique aesthetic advantages for design projects. Its raw, industrial look adds a modern touch to both functional and decorative spaces. The natural finish highlights the texture and steel's innate beauty. This creates a bold statement in various applications, such as walkways or architectural features.

Incorporating mill finish steel grating can enhance visual interest. Designers appreciate the versatility it brings. The neutrality of the finish allows it to pair well with various materials, such as wood or glass. This balance can be striking, yet sometimes it might feel too stark or cold. It’s essential to consider how lighting and surrounding elements influence the overall effect.

**Tips:** Experiment with colors and finishes around the grating. Adding plants can soften the look and create contrast. Be aware of maintenance; the finish’s variation might not always be uniform. A certain charm comes from its imperfections. Embrace these nuances to achieve a more rustic and authentic appearance.

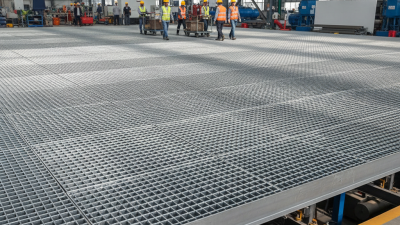

Mill finish steel grating solutions offer excellent maintenance and longevity. Their surface is smooth, reducing dirt accumulation and providing easier cleaning options. This characteristic is particularly beneficial for industrial environments where cleanliness is crucial. Regular maintenance involves simple washing to prevent rust and corrosion, extending the lifespan of the grating.

Tips: Inspect the grating periodically for any signs of wear. Pay close attention to edges and joints. A small issue can turn into a bigger problem if ignored.

Another advantage is the weather resistance of mill finish steel. It performs well under various conditions, but some exposure may lead to superficial rust. This is common and manageable with proper protective routines. Keeping a maintenance log can help track repair needs over time.

Tips: Use a non-abrasive cleaner to maintain the surface finish. Consider applying a protective sealant every few years to enhance durability. Regular checks can prevent costly replacements.

| Benefit | Description | Longevity Impact | Maintenance Requirements |

|---|---|---|---|

| Cost-Effectiveness | Affordable upfront costs compared to other materials. | High durability ensures long-term savings. | Minimal maintenance needed. |

| Versatility | Suitable for various applications in construction and industrial uses. | Long-lasting design across different environments. | Occasional cleaning to maintain appearance. |

| Strength | High load-bearing capacity prevents deformation under stress. | Exceptional durability extends lifespan. | Periodic inspections recommended. |

| Security | Provides a secure platform and minimizes slip hazards. | Well-maintained surfaces enhance safety. | Regular cleaning to prevent debris accumulation. |

| Aesthetic Appeal | Offers a clean, industrial look that complements modern designs. | Maintaining a polished appearance is easy. | Simple surface cleaning is sufficient. |

| Corrosion Resistance | Resistant to rust and other environmental factors. | Enhances longevity in harsh conditions. | Periodic inspection and maintenance advised. |

| Eco-Friendly | Made from recyclable materials, reducing environmental impact. | Sustainability contributes to long-term use. | Minimal maintenance required to uphold sustainability. |

| Lightweight | Easy to install and maneuver compared to heavier alternatives. | Saves resources in transport and installation. | Little to no maintenance required. |

| Customizable Options | Available in various sizes and configurations to fit project needs. | Tailored solutions improve longevity by optimizing fit. | Maintenance based on specific installation conditions. |