Low Carbon Steel Grating has emerged as a vital component in sustainable construction solutions, offering both environmental and economic benefits. According to the Global Steel Innovations Forum, the construction industry contributes approximately 39% of global carbon emissions, highlighting an urgent need for more sustainable alternatives. Utilizing Low Carbon Steel Grating not only reduces the overall carbon footprint but also enhances durability and longevity, making it a cost-effective choice over time. A study by the Environmental Protection Agency shows that materials with lower carbon content can significantly decrease greenhouse gas emissions during production and use. Moreover, Low Carbon Steel Grating is recyclable, furthering its appeal in green building initiatives. As architects and builders face increasing pressure to adopt sustainable practices, understanding and leveraging the advantages of Low Carbon Steel Grating can pave the way for a more eco-friendly future in construction.

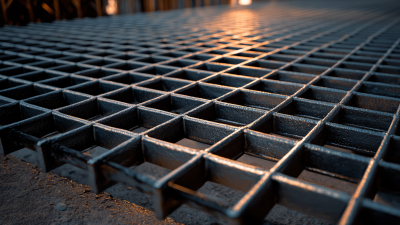

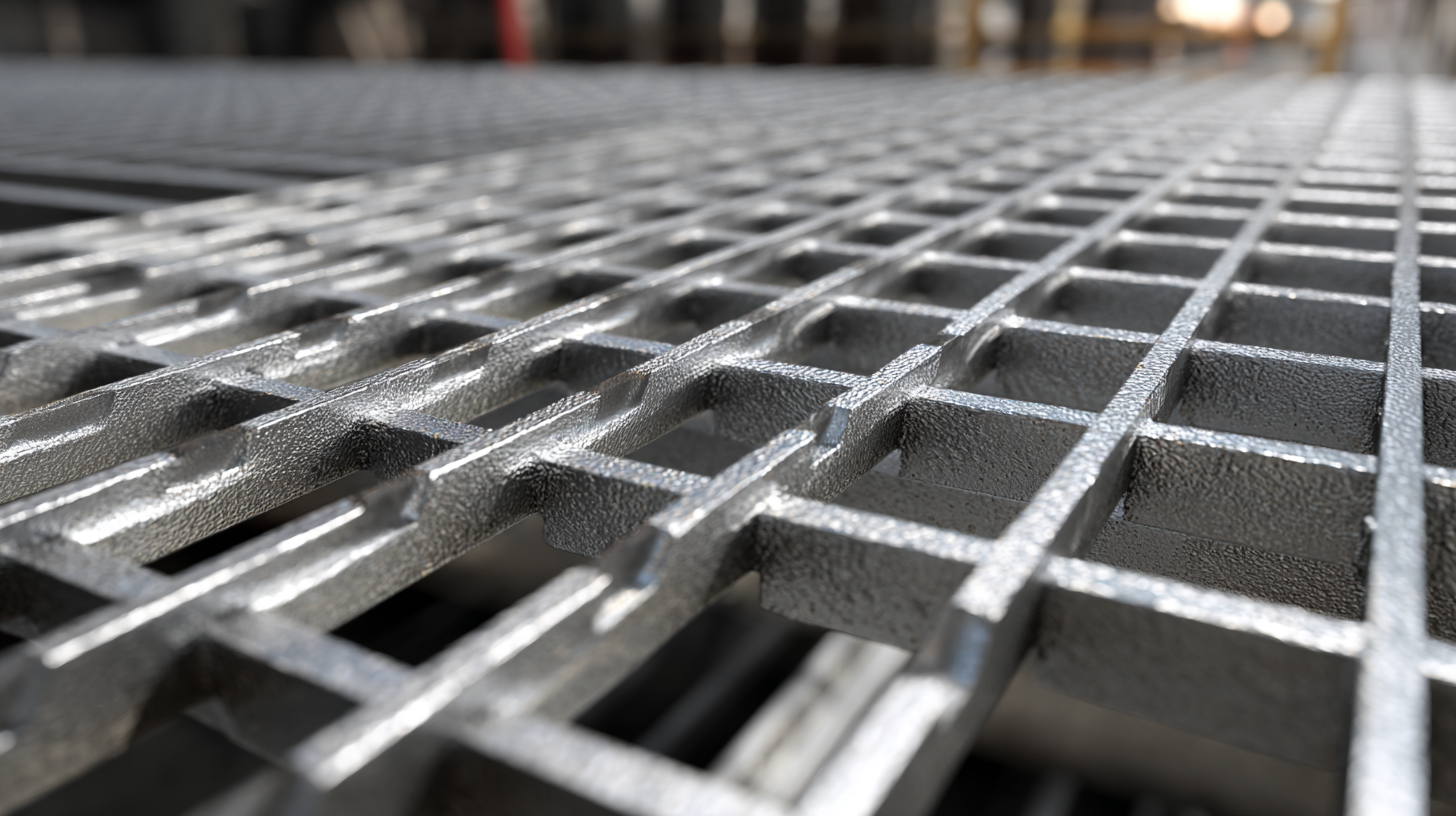

Low carbon steel grating has emerged as a pivotal material in sustainable construction, offering numerous advantages that align with eco-friendly building practices. This type of grating, made from low carbon steel, is characterized by its strength, durability, and recyclability. It serves various structural and aesthetic purposes in construction, including walkways, flooring, and safety barriers. By utilizing low carbon steel, builders can reduce the overall carbon footprint of a project, as this material typically requires less energy to produce compared to higher carbon alternatives.

Moreover, low carbon steel grating contributes to sustainability through its longevity and maintenance-friendly properties. The material is resistant to corrosion and requires minimal upkeep, leading to longer life cycles and less frequent replacement. Additionally, the lightweight nature of low carbon steel means easier transportation and installation, further decreasing energy consumption during the construction process. As a result, incorporating low carbon steel grating not only enhances the efficiency of construction projects but also supports overall sustainability goals within the building industry.

Low carbon steel grating is increasingly recognized for its significant contributions to

sustainable construction, particularly in terms of environmental impact and carbon footprint reduction. According to a report by

the World Steel Association, the steel industry accounts for approximately 7% of global carbon emissions; thus, the shift to low carbon steel can play a crucial role in

sustainability efforts. Low carbon steel grating, produced with reduced carbon content, results in lower emissions during manufacturing compared to

traditional steel products. This reduction not only mitigates the overall carbon footprint associated with construction but also aligns with the goals set forth in various

sustainability initiatives worldwide.

Low carbon steel grating is increasingly recognized for its significant contributions to

sustainable construction, particularly in terms of environmental impact and carbon footprint reduction. According to a report by

the World Steel Association, the steel industry accounts for approximately 7% of global carbon emissions; thus, the shift to low carbon steel can play a crucial role in

sustainability efforts. Low carbon steel grating, produced with reduced carbon content, results in lower emissions during manufacturing compared to

traditional steel products. This reduction not only mitigates the overall carbon footprint associated with construction but also aligns with the goals set forth in various

sustainability initiatives worldwide.

Furthermore, low carbon steel grating offers durability and longevity, which enhances its overall sustainability profile. Research from the American Iron and Steel Institute indicates that using low carbon steel

can extend the lifecycle of construction materials, leading to less frequent replacements and a decrease in resource consumption over time. This longevity is essential in minimizing waste and conserving energy in the production and transportation of replacement materials.

As construction projects aim for higher environmental standards, integrating low carbon steel grating can be an effective strategy to enhance both performance and sustainability, ultimately contributing to

greener infrastructures.

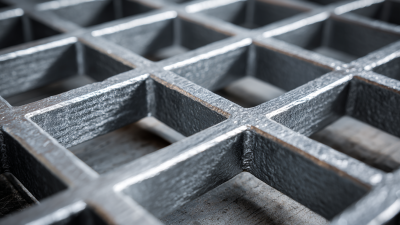

Low carbon steel grating offers a remarkable alternative to traditional construction materials, particularly when sustainability is a primary consideration. Unlike conventional materials such as concrete and heavier steel, low carbon steel grating is lightweight yet robust, making it easier to transport and install. Its inherent recyclability also reduces the environmental footprint associated with construction. As industries strive to meet stringent environmental regulations, adopting materials that minimize carbon emissions can significantly contribute to overall sustainability efforts.

When comparing low carbon steel grating with traditional materials, it becomes evident that the former promotes better resource efficiency. Traditional materials often require extensive energy for production and have a larger carbon footprint over their lifespan. In contrast, low carbon steel grating not only utilizes fewer raw materials but also can be manufactured through processes that consume less energy. Moreover, its longevity reduces the frequency of replacements, further supporting sustainable construction practices. By integrating low carbon steel grating into building designs, construction professionals can achieve eco-friendly solutions that align with modern sustainability goals.

| Criteria | Low Carbon Steel Grating | Traditional Materials |

|---|---|---|

| Material Strength | High | Variable |

| Weight | Lightweight | Heavy |

| Corrosion Resistance | Moderate | Low |

| Recyclability | 100% | Limited |

| Cost Effectiveness | Economic | Varies |

| Environmental Impact | Low | High |

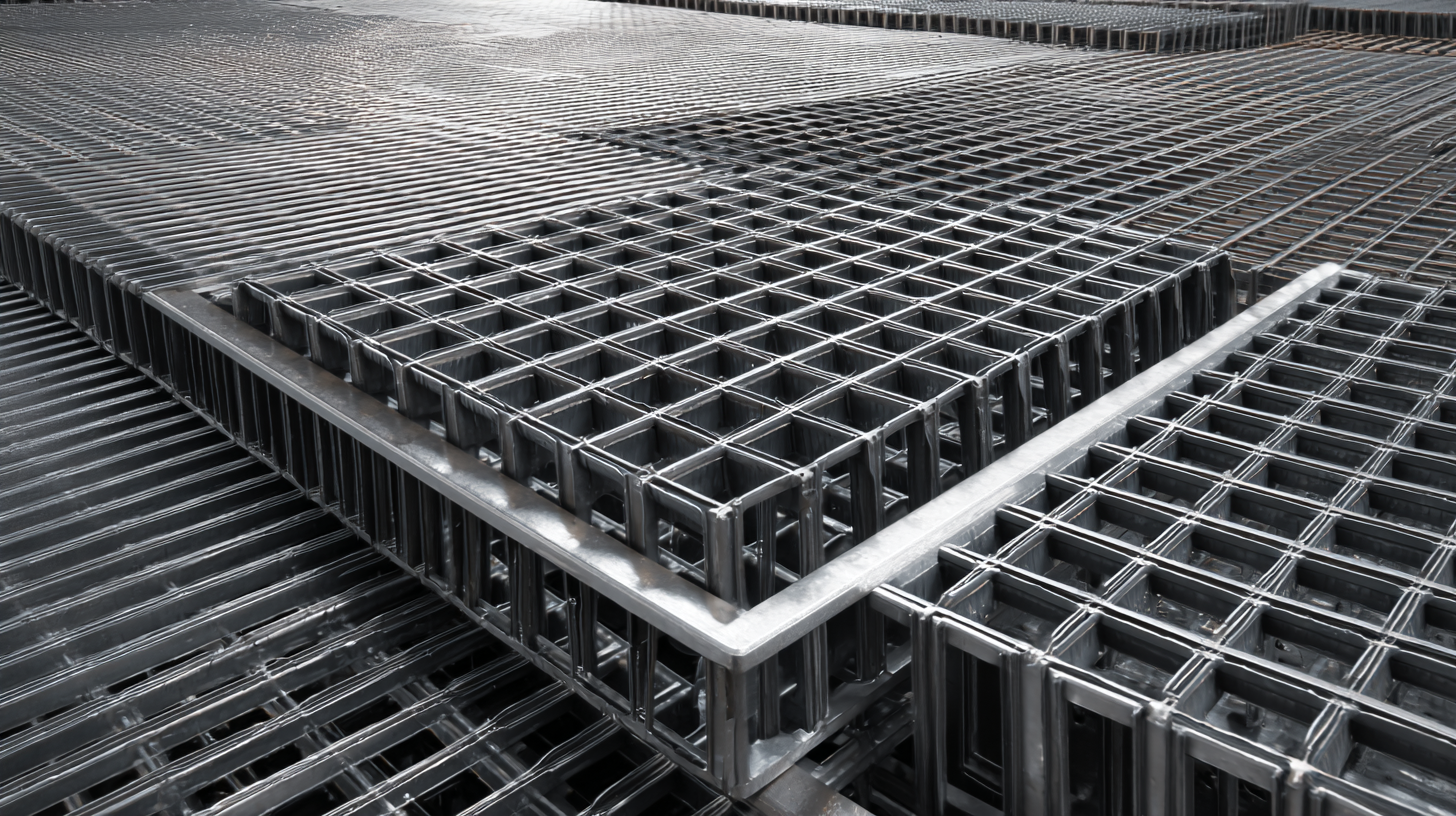

The construction industry is witnessing a remarkable shift towards sustainable practices, with low carbon steel grating gaining significant attention as a preferred material. Recent industry statistics indicate a growing demand for low carbon solutions, driven by heightened environmental awareness and regulatory pressures. As construction projects increasingly prioritize sustainability, low carbon steel grating not only meets structural needs but also offers advantages in reducing the overall carbon footprint.

In addition to environmental benefits, low carbon steel grating presents a cost-effective solution for many construction applications. Its durability and strength reduce the need for frequent replacements, thereby minimizing waste and long-term expenses. Data from recent market analyses reveal a steady increase in projects incorporating low carbon materials, reflecting a broader trend in the sector. This shift underscores the importance of innovation and environmentally responsible materials in modern construction, paving the way for a sustainable future.

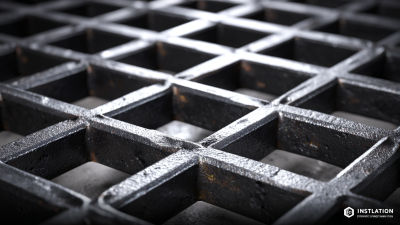

Implementing low carbon steel grating in sustainable building designs not only enhances structural integrity but also contributes to environmental conservation. According to the World Steel Association, low carbon steel emits significantly less CO2 during production compared to traditional steel, with potential reductions up to 20% depending on the manufacturing process. This characteristic makes it an attractive option for architects and builders looking to minimize their carbon footprint while maintaining durability.

Best practices for integrating low carbon steel grating involve detailed planning and collaboration among stakeholders. Designers should utilize the latest simulation software to predict the performance and lifespan of the materials, thereby optimizing their application within the structure. Additionally, using low carbon steel grating in green roofs or as part of drainage systems can help manage stormwater effectively, reducing urban runoff.

The U.S. Green Building Council indicates that implementing such materials in construction can contribute to LEED certification, further reinforcing the trend towards sustainability in architecture. By adopting these practices, the construction industry can lead the way in embracing innovative, eco-friendly solutions.