Grating Galvanized steel has emerged as a crucial component in various industrial and construction applications, renowned for its durability and resistance to corrosion. According to industry expert John Smith, "The use of Grating Galvanized steel not only enhances structural integrity but also prolongs the lifespan of installations, making it an invaluable asset in demanding environments." This material is often preferred for walkways, platforms, and stair treads due to its slip-resistant surface and ability to bear heavy loads, crucial factors for ensuring safety and efficiency in workplaces.

The benefits of Grating Galvanized extend beyond its physical characteristics. Its fabrication process involves galvanization, which significantly improves its resistance to rust and environmental degradation, thereby reducing maintenance costs over time. Many manufacturers are turning to this innovative form of steel grating as a sustainable solution that not only meets strict industry standards but also contributes to the overall efficiency of construction projects. Consequently, adopting Grating Galvanized in design and construction processes leads to smarter choices that favor both economic and ecological sustainability, paving the way for future advancements in the industry.

Grating galvanized steel has emerged as a vital material in various industrial and construction applications, primarily due to its robust characteristics and functional advantages. One of the most significant benefits of using grating galvanized steel is its exceptional resistance to corrosion.

The galvanization process involves coating the steel with a layer of zinc, which acts as a shield against environmental factors that typically deteriorate unprotected steel. This makes galvanized grating ideal for outdoor applications or environments where moisture and chemicals are prevalent, ensuring longevity and reducing maintenance costs over time.

Moreover, grating galvanized steel offers excellent load-bearing capabilities while maintaining a lightweight profile, making it easy to handle and install. This combination of strength and reduced weight allows for more versatile designs in flooring, walkways, and platforms, where safety and accessibility are paramount. Additionally, the slip-resistant surface of galvanized grating enhances safety in industrial settings, helping to prevent accidents in high-traffic areas. As industries continually seek efficiency and durability in construction materials, the advantages of grating galvanized steel position it as a top choice for modern applications.

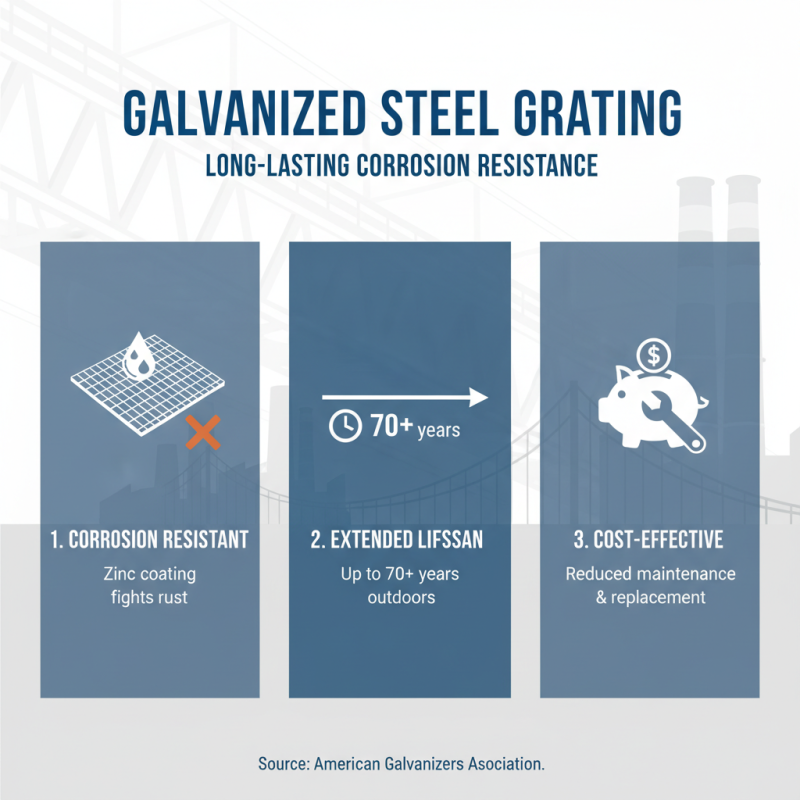

Galvanized steel grating has become a preferred choice in industrial and construction sectors due to its remarkable corrosion resistance and extended lifespan. A report from the American Galvanizers Association highlights that galvanized steel can withstand corrosive environments, enduring up to 70 years in outdoor applications, depending on environmental exposure. The galvanization process, which involves coating steel with zinc, creates a protective layer that significantly reduces rust formation and extends the material’s functional life, making it a cost-effective solution over time.

In addition to its durability, galvanized steel grating offers enhanced safety in various settings. The National Institute for Occupational Safety and Health (NIOSH) indicates that using corrosion-resistant materials in industrial flooring reduces maintenance costs and minimizes the risk of accidents related to structural failure. By significantly improving longevity, businesses can allocate their resources more efficiently and rely on stronger, safer infrastructure. This not only ensures compliance with safety regulations but also contributes to environmental sustainability by reducing the frequency of replacements and waste generation, showcasing a progressive approach in modern construction and industrial applications.

Galvanized steel grating has become an essential component in various industrial settings, primarily due to its enhanced safety features. One of the key advantages is its slip-resistant surface, which significantly reduces the risk of accidents in environments where moisture, oils, or other substances may create slippery conditions. The grid design of the grating allows for excellent traction, enabling workers to navigate safely, even in harsh weather conditions. This characteristic is particularly vital in manufacturing plants, warehouses, and construction sites where heavy machinery and foot traffic are prevalent.

Additionally, the corrosion-resistant properties of galvanized steel contribute to a safer work environment. The galvanization process coats the steel with a protective layer that combats rust and degradation, ensuring longevity and reliability. As a result, facilities are less likely to encounter hazardous conditions arising from deteriorating materials. This durability extends the lifespan of the grating, reducing the need for frequent replacements and maintenance, which can often lead to unsafe working situations during repairs. Ultimately, the choice of galvanized steel grating promotes not only a higher standard of safety but also enhances overall operational efficiency in industrial applications.

| Benefit | Description | Impact on Safety | Application Areas |

|---|---|---|---|

| Corrosion Resistance | Galvanized steel grating is coated with zinc, which protects the steel from rusting and extends its lifespan. | Reduces the risk of structural failure due to corrosion-related weakness. | Outdoor platforms, industrial walkways, and drainage covers. |

| Slip Resistance | The design of the grating allows for excellent traction, minimizing slip hazards. | Improves worker safety by reducing slip and fall accidents. | Stair treads, catwalks, and access platforms. |

| Lightweight Yet Strong | Galvanized steel grating is structurally sound while being significantly lighter than solid steel plates. | Facilitates safer handling and reduces the risk of injuries from lifting heavy materials. | Construction sites, factory floorings, and maintenance areas. |

| Enhanced Visibility | Open grating design allows light and visibility for better surveillance. | Improves situational awareness, leading to proactive safety measures. | Elevated walkways, loading docks, and safety platforms. |

| Easy Maintenance | Galvanized steel grating is easier to clean and maintain than other materials. | Reduced downtime for maintenance leads to increased productivity and safety. | Food processing plants, chemical facilities, and wastewater treatment plants. |

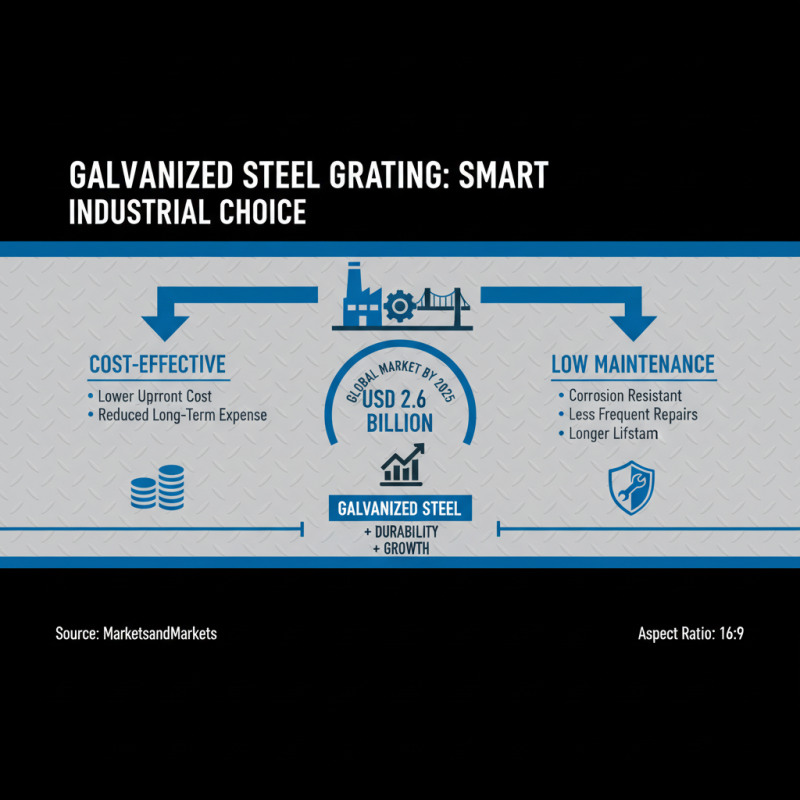

Galvanized steel grating has emerged as a favored choice in industrial and construction applications due to its impressive cost-effectiveness and low maintenance requirements. According to a recent report by MarketsandMarkets, the global market for steel grating is projected to reach USD 2.6 billion by 2025, with galvanized steel accounting for a significant portion of that growth. This material undergoes a protective zinc coating process, which not only enhances its durability but also significantly reduces the frequency and cost of maintenance compared to non-galvanized alternatives.

In terms of maintenance benefits, galvanized steel grating exhibits superior resistance to corrosion. The National Association of Corrosion Engineers (NACE) estimates that corrosion costs the US economy upwards of USD 276 billion annually. By utilizing galvanized steel, companies can mitigate these costs as the longevity of the grating reduces the need for frequent replacements or refurbishments. Furthermore, its slip-resistant surface ensures safety in industrial environments, thereby minimizing the risk of workplace accidents and associated liabilities. This combination of longevity and safety reinforces the financial viability of investing in galvanized steel grating for various applications across multiple sectors.

Galvanized steel grating is a highly versatile solution for various industrial and construction applications. Its ability to withstand harsh environments while offering lightweight and durable support makes it an ideal choice for walkways, platforms, and drainage systems. The customization options further enhance its utility, allowing businesses to tailor the design to specific operational needs, from mesh size and spacing to surface finish and coating types. This adaptability ensures that galvanized steel grating can fit seamlessly into diverse projects, optimizing both functionality and aesthetics.

When considering galvanized steel grating, it's essential to assess the environment where it will be used. For instance, in corrosive environments, opting for additional surface treatments can significantly increase longevity. Moreover, selecting the right gauge of steel can impact not only strength but also weight, which is crucial for installation processes.

Tips: Keep in mind that effective drainage is vital in industrial settings, and using grating with larger openings can facilitate better water runoff. Additionally, always consult with suppliers about customization options that can enhance safety and performance, such as slip-resistant surfaces or specific sizes that meet regulatory requirements. By making informed choices, you can optimize the advantages of galvanized steel grating for your specific project needs.

This chart illustrates the various benefits of using galvanized steel grating in industrial and construction applications. Each benefit is rated on a scale from 1 to 10, highlighting the advantages such as corrosion resistance and versatility, which make galvanized steel a preferred choice in many projects.

Grating galvanized steel offers numerous advantages essential for industrial and construction applications. Its enhanced corrosion resistance significantly prolongs the lifespan of structures, making it a reliable choice for harsh environments. Additionally, the safety features of grating galvanized steel, including slip resistance and strength, provide critical support in preventing accidents in industrial settings.

Cost-effectiveness is another benefit, as the low maintenance requirements help reduce overall expenditures. Moreover, the versatility and customization options available for grating galvanized solutions ensure they can meet various project needs. Finally, compliance with industry standards and regulations reinforces the credibility and applicability of galvanized steel grating, making it a favored material in construction and industry sectors.