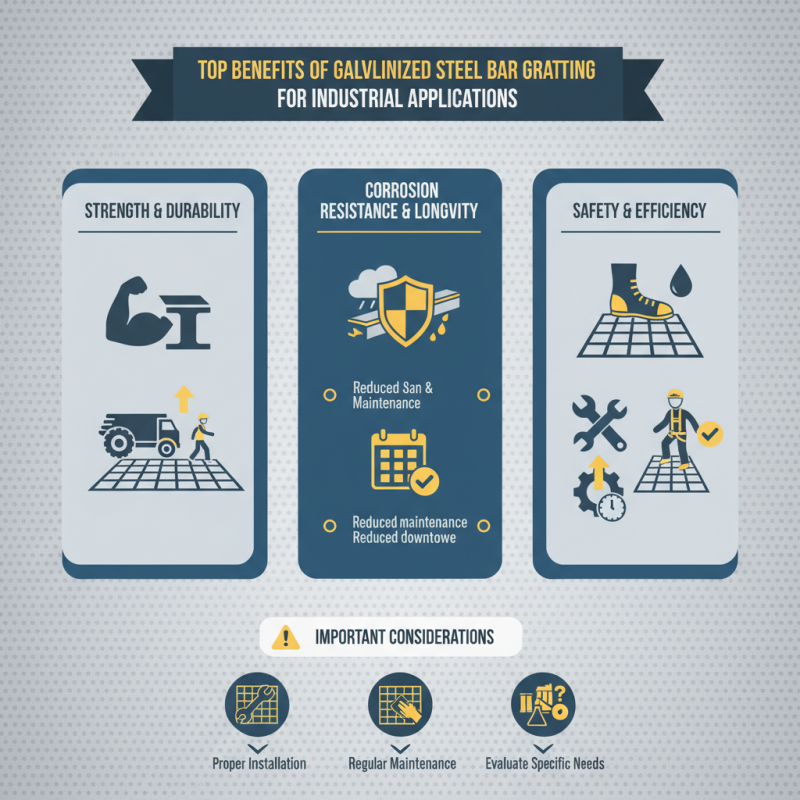

Galvanized Steel Bar Grating is gaining popularity in various industrial settings. This material offers numerous advantages that enhance safety and functionality. Its strength and durability make it suitable for heavy loads. Many industries rely on this type of grating for walkways, platforms, and drainage covers.

The protective coating of galvanized steel ensures resistance to rust and corrosion. This feature significantly extends its lifespan, reducing maintenance costs. Many facilities benefit from reduced downtime, thanks to this resilience. The lightweight nature of galvanized steel also aids in easier installation and modifications. Workers find it safer to navigate over grating that provides excellent traction even in wet conditions.

Despite its benefits, users must consider specific factors. Proper installation is critical for maximizing performance. Neglecting to maintain the grates can lead to safety risks. Additionally, not every application may require galvanized steel. It's essential to evaluate needs carefully. Galvanized Steel Bar Grating is a reliable choice, but users should always reflect on their particular situation.

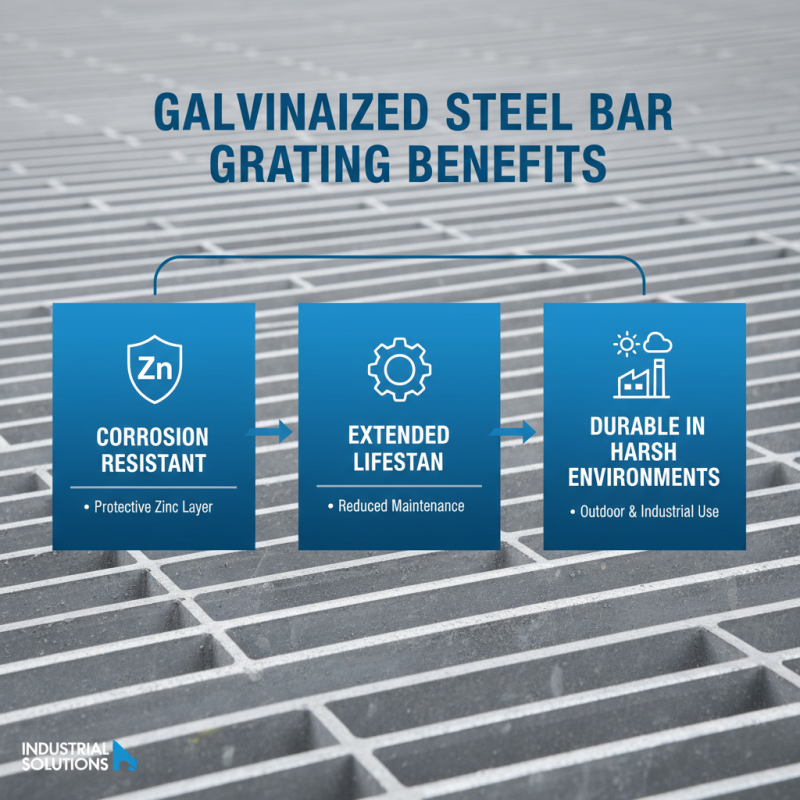

Galvanized steel bar grating offers numerous advantages for industrial applications. One of its key properties is durability. The galvanizing process provides a protective layer against corrosion. This extends the lifespan of the grating, making it ideal for outdoor and harsh environments.

Another important property is its lightweight nature. Despite being strong, galvanized steel bar grating is easier to handle during installation. This can lead to reduced labor costs and time spent on projects. However, don't underestimate the need for proper support. Inadequate support may lead to structural issues over time.

**Tip:** Always assess your specific needs when choosing steel bar grating. Consider the load requirements and environmental factors.

Versatility is another benefit. Galvanized steel bar grating can adapt to different shapes and sizes. Whether you need it for walkways, platforms, or drainage covers, it fits the bill. Still, one must be cautious about overloading. Exceeding weight limits can cause buckling and safety hazards.

**Tip:** Regular inspections will ensure long-term performance and safety. Maintenance can prevent potential problems down the line.

Galvanized steel bar grating is well-known for its exceptional durability. It effectively withstands harsh conditions found in industrial settings. The galvanized coating provides a barrier against moisture, chemicals, and extreme temperatures. This resilience helps minimize maintenance costs over time. Facilities can operate with confidence, knowing their flooring or platforms remain intact.

Corrosion resistance is crucial in environments exposed to dampness. It extends the lifespan of the grating. Industrial sectors such as manufacturing, wastewater, and chemical processing benefit significantly. Yet, not all galvanization processes are equal. Some coatings may wear off faster under specific circumstances. Choosing high-quality material is vital for optimal performance.

Another consideration is weight. Galvanized steel grating is strong but can be heavy. Installing it in some areas may pose challenges. Ensuring proper installation is essential to avoid future issues. Taking these factors into account can greatly enhance long-term utility. Balancing cost and quality is key in these decisions.

Galvanized steel bar grating is gaining popularity in industrial applications. Its cost-effectiveness is a major factor driving this trend. According to the Global Market Insights report, the demand for steel grating solutions is projected to increase due to their durability and low maintenance costs.

Investing in galvanized steel can yield significant long-term savings. These structures resist corrosion, reducing the need for frequent replacements. A study by the Steel Bar Grating Manufacturers Association highlights that projects using galvanized steel save up to 30% on maintenance costs compared to traditional materials. Additionally, the material is easy to install, cutting labor costs further.

Tips: Consider the weight load of your application. Make sure the selected grating can handle the expected traffic. Regular inspections can extend its lifespan, even when made of durable materials. Don’t underestimate the importance of proper installation. A poorly installed grating can lead to safety hazards and additional costs down the line.

Galvanized steel bar grating serves many industries. It provides a reliable flooring solution in warehouses, factories, and power plants. The grating’s slip-resistant surface ensures safety in areas with heavy foot and vehicle traffic. This material holds up well in harsh conditions, making it a top choice for outdoor applications.

In the construction sector, it’s often used for walkways and stair treads. This versatility is appealing to architects and engineers. Pharmaceutical and food processing facilities also benefit from its cleanability. The smooth surface reduces bacteria build-up, which is crucial for maintaining health standards. However, some environments might pose challenges, like excessive corrosion in coastal areas.

The grating is lightweight yet strong, ensuring easy installation and maintenance. It’s available in various sizes and configurations, allowing customization for specific needs. Yet, improper installation can lead to safety hazards. Regular inspections are essential to address wear and tear. Overall, galvanized steel bar grating proves beneficial across many sectors but requires ongoing attention.

Galvanized steel bar grating is known for its safety features. One critical advantage is its slip resistance. This is especially vital in industrial settings where spills can occur. The openings in the grating allow liquids to drain away. As a result, the surface remains safer for workers.

Another essential aspect is load-bearing capacity. According to the American Institute of Steel Construction, properly designed bar grating can support loads over 1,500 pounds. This makes it useful in various applications, from walkway grating to heavy machinery support. However, not all installations adhere to best practices. Regular inspections of load limits and conditions are necessary to prevent failures.

Moreover, galvanized steel does resist corrosion. This increases its longevity. A study from the International Journal of Metal Structures highlights that galvanized coatings can last up to 50 years. Yet, improper maintenance can reduce this lifespan. Rust may form in damaged areas. Users must remain vigilant about the condition of the grating.