In the realm of industrial applications, the choice of flooring materials and grating systems plays a crucial role in ensuring safety, efficiency, and durability. One such innovative solution is Black Plain Grating, which has gained significant traction in various sectors. According to a report by MarketsandMarkets, the global grating market is projected to reach USD 4.6 billion by 2026, driven by the increasing demand for high-quality and versatile flooring options.

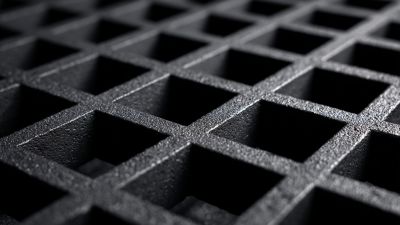

Black Plain Grating not only meets stringent safety standards but also enhances the aesthetic appeal of industrial spaces. Its robust design and ability to withstand heavy loads make it a popular choice in manufacturing, chemical processing, and oil and gas sectors. In 2023, understanding the advantages of Black Plain Grating is essential for industries aiming to optimize their operational efficiency while ensuring worker safety.

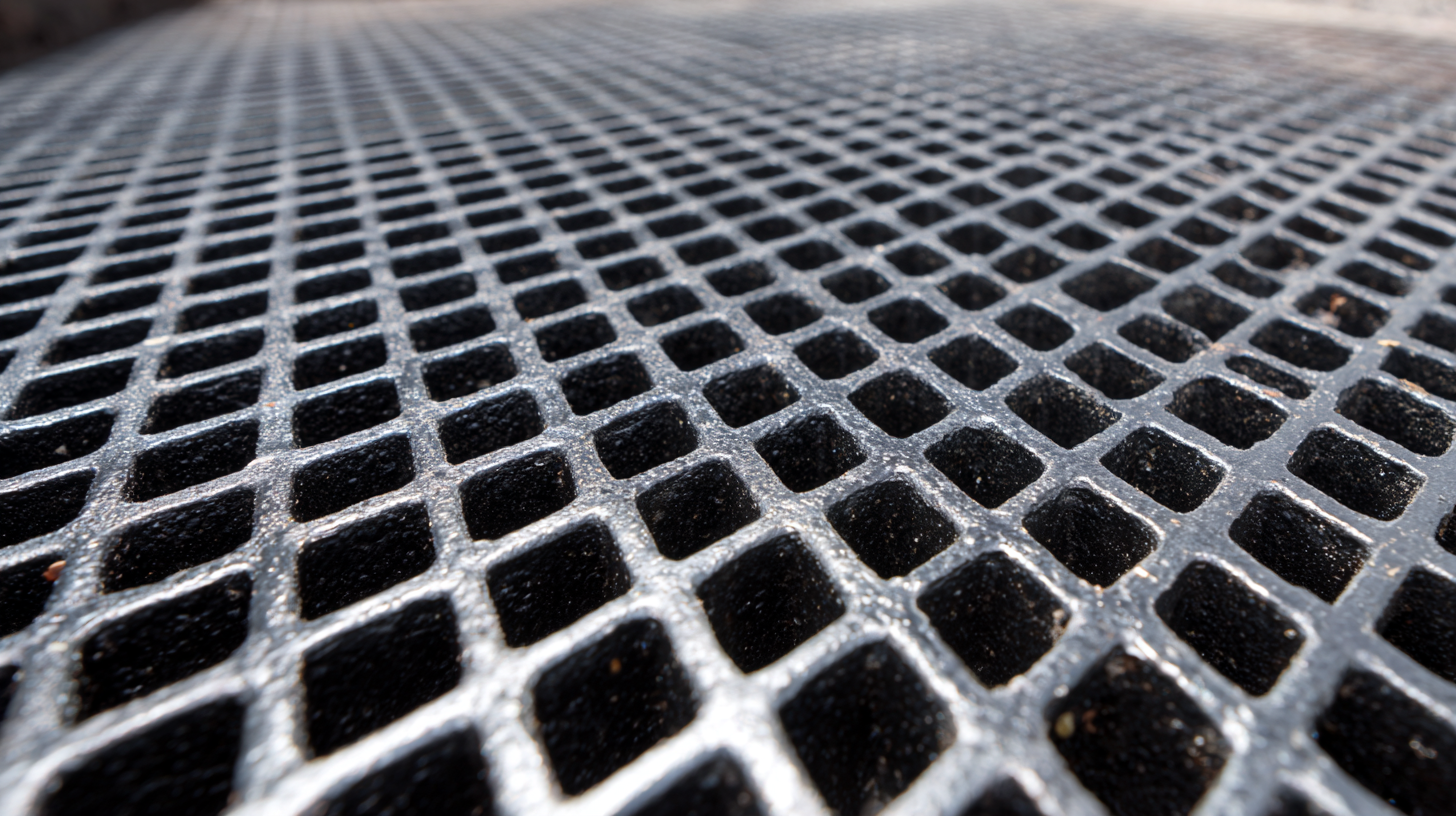

In heavy-duty industrial settings, black plain grating has emerged as a preferred choice due to its unique properties and practical advantages. One of the key benefits is its enhanced load-bearing capacity; according to the American National Standards Institute (ANSI), properly designed grating can support loads of up to 1,800 pounds per square foot. This makes it ideally suited for environments where heavy machinery is regularly operated. Additionally, black plain grating typically features a non-slip surface, which improves safety in industrial workplaces, as a report by the Occupational Safety and Health Administration (OSHA) indicates that slip hazards account for over 30% of workplace injuries.

Tip: When selecting black plain grating for your facility, consider choosing products that meet ANSI/NAAMM standards for strength and safety to ensure compliance and durability.

Another advantage of black plain grating is its resistance to corrosion and chemicals, vital in industries such as petrochemicals and pharmaceuticals. A recent market analysis by Grand View Research highlighted that the demand for corrosion-resistant grating is projected to grow by 5% annually through 2025. This durability not only extends the lifespan of the grating but also reduces maintenance costs significantly.

Tip: Regular maintenance checks can further enhance the lifespan of your black plain grating; schedule inspections at least bi-annually to identify and address wear and tear early.

| Benefit | Description | Typical Applications | Durability Level |

|---|---|---|---|

| High Load-Bearing Capacity | Designed to support heavy equipment and loads without deformation. | Manufacturing plants, warehouses | Excellent |

| Corrosion Resistance | Protected against rust and corrosion from harsh environments. | Chemical processing, outdoor applications | High |

| Versatile Design | Can be customized in various sizes and shapes to meet specific needs. | Custom manufacturing, construction | Medium |

| Non-Slip Surface | Provides safety in wet or oily conditions, reducing slip hazards. | Food processing, maintenance areas | High |

| Easy Installation | Quick to install and replace, minimizing downtime. | Industrial flooring, platforms | High |

| Cost-Effectiveness | Offers high performance at a competitive price compared to alternatives. | Budget-conscious projects, facilities | Medium |

| Low Maintenance | Requires minimal upkeep, saving on maintenance costs and efforts. | Long-term installations, remote locations | High |

Black plain grating has rapidly emerged as a top choice for various industrial applications, particularly due to its superior durability. Crafted from high-quality materials, this type of grating is engineered to withstand harsh environments, making it ideal for factories, warehouses, and outdoor settings. Its resistance to corrosion, rust, and impact ensures that it maintains structural integrity even under extreme conditions. As industries strive for cost-effectiveness, the longevity of black plain grating significantly reduces the need for frequent replacements, leading to considerable savings over time.

Black plain grating has rapidly emerged as a top choice for various industrial applications, particularly due to its superior durability. Crafted from high-quality materials, this type of grating is engineered to withstand harsh environments, making it ideal for factories, warehouses, and outdoor settings. Its resistance to corrosion, rust, and impact ensures that it maintains structural integrity even under extreme conditions. As industries strive for cost-effectiveness, the longevity of black plain grating significantly reduces the need for frequent replacements, leading to considerable savings over time.

Furthermore, the inherent strength of black plain grating allows it to bear heavy loads without warping or bending. This reliability adds an extra layer of safety for workers and equipment alike, which is crucial in high-traffic industrial areas. Additionally, the sleek black finish not only provides a modern aesthetic but also enhances visibility and safety in dimly lit environments. By choosing black plain grating, industries can invest in a solution that not only meets their operational demands but also stands the test of time, ensuring a robust and sustainable infrastructure.

In today’s industrial landscape, cost-effectiveness is a paramount concern for facility managers and procurement specialists. Black plain grating, known for its durability and versatility, stands out as a viable solution that can significantly maximize your budgeting efforts. According to a market report by Research and Markets, the industrial grating market is projected to reach nearly $6 billion by 2025, with black plain grating being a major contributor due to its affordability and long lifespan, making it an excellent investment for various applications.

The initial purchase price for black plain grating is often lower compared to other materials, yet its resilience plays a critical role in overall cost savings. Data from the American National Standards Institute (ANSI) indicates that properly maintained grating can last over 30 years, reducing the frequency and cost of replacements. Additionally, the ease of installation minimizes labor costs, with many contractors reporting up to 25% savings in installation time when utilizing black plain grating over more complex systems. This combination of low initial costs and long-term value makes black plain grating an essential option for industries looking to optimize their budgets efficiently.

This bar chart illustrates the cost-effectiveness of Black Plain Grating in various dimensions relevant to industrial applications. Each rating reflects the perceived advantages in material cost, installation, maintenance, durability, and weight management on a scale from 1 to 10.

In industrial settings, safety is of paramount importance, and one of the most effective ways to enhance safety is through the use of black plain grating. This material is engineered to provide superior slip resistance, a vital feature for environments prone to spills and wet conditions. According to a report by the National Safety Council, falls account for approximately 29% of all workplace injuries, making the choice of flooring materials critical. Black plain grating, with its specialized surface texture, significantly reduces the likelihood of slips and falls, especially in high-traffic areas where safety hazards are most prevalent.

Moreover, the slip resistance of black plain grating is often quantified through the coefficient of friction (COF) testing. Studies show that properly designed grating can achieve a COF well above the minimum safety threshold of 0.5 recommended by the American National Standards Institute (ANSI). This not only complies with industry safety standards but also creates a more secure work environment. Additionally, the dark color of the black plain grating helps in masking dirt and grime, maintaining a cleaner appearance while allowing for easier identification of any potential hazards. This combination of functionality and safety makes black plain grating an essential component in modern industrial applications.

Black plain grating has emerged as a premier choice in various industrial applications, thanks to its lightweight yet resilient design. Industries such as manufacturing, construction, and transportation leverage black plain grating for its versatility. According to a recent report by Grand View Research, the global industrial grating market is projected to reach

$2.19 billion by 2025, evidencing the growing reliance on materials like black plain grating due to their strength and durability in demanding environments.

One of the most common applications of black plain grating is in walkways and platforms, where safety is paramount. With a load-bearing capability that significantly reduces the risk of slips and falls, it provides a reliable surface for workers. Furthermore, in the petrochemical sector, black plain grating replaces heavier steel options, contributing to weight reduction without sacrificing structural integrity. This is crucial in environments where equipment must remain portable yet sturdy.

Tip: When selecting black plain grating, ensure that it meets the appropriate load-bearing specifications for your specific application. Additionally, consider the coating options available to enhance corrosion resistance, particularly in harsher industrial settings. Tip: Regular maintenance checks can prolong the lifespan of your grating, ensuring safety standards are consistently met while minimizing replacement costs.