In recent years, the construction and industrial sectors have increasingly prioritized safety and durability, leading to a reevaluation of traditional materials such as Serrated Steel Grating. According to a report by the Occupational Safety and Health Administration (OSHA), slip and fall incidents account for a staggering 30% of all reported workplace injuries, highlighting the necessity for grating solutions that enhance traction and safety. While Serrated Steel Grating has been a popular choice due to its design that allows for effective drainage and stability, innovative alternatives are emerging that may offer superior performance in terms of slip resistance and longevity. A study by the American Institute of Steel Construction suggests that advancements in composite materials and specialized coatings can significantly outperform traditional steel, providing enhanced safety in demanding environments. This blog explores these innovative alternatives, aiming to shed light on how they can better serve the safety needs of various industries while ensuring durability and cost-effectiveness.

In recent years, the construction and industrial sectors have increasingly prioritized safety and durability, leading to a reevaluation of traditional materials such as Serrated Steel Grating. According to a report by the Occupational Safety and Health Administration (OSHA), slip and fall incidents account for a staggering 30% of all reported workplace injuries, highlighting the necessity for grating solutions that enhance traction and safety. While Serrated Steel Grating has been a popular choice due to its design that allows for effective drainage and stability, innovative alternatives are emerging that may offer superior performance in terms of slip resistance and longevity. A study by the American Institute of Steel Construction suggests that advancements in composite materials and specialized coatings can significantly outperform traditional steel, providing enhanced safety in demanding environments. This blog explores these innovative alternatives, aiming to shed light on how they can better serve the safety needs of various industries while ensuring durability and cost-effectiveness.

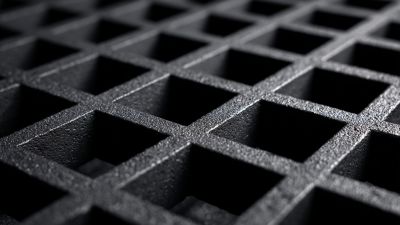

The traditional use of serrated steel grating in various applications has long been valued for its slip-resistant properties. However, as industries evolve, there’s a growing shift towards innovative materials that offer enhanced safety and durability. Advanced composites, for instance, have emerged as a formidable alternative due to their lightweight nature and resistance to corrosive environments. These materials not only outperform steel grating in terms of longevity but also reduce maintenance costs, making them more economically viable in the long run.

When considering alternatives to serrated steel grating, it's crucial to evaluate the specific requirements of your application. Select materials that offer optimal slip resistance tailored to your environmental conditions. For instance, materials infused with anti-slip technologies can further enhance safety in wet or oily environments.

Additionally, the adoption of advanced composites should include a comprehensive understanding of their load-bearing capabilities. Always consult with material experts to ensure that your choice meets or exceeds the necessary safety standards. This proactive approach not only boosts performance but can also significantly improve user safety in environments where footing stability is critical.

In recent years, workplace safety has become a paramount concern across industries, prompting a reevaluation of traditional materials such as serrated steel grating. According to a report by the National Safety Council, falls remain one of the leading causes of workplace injuries, contributing to over 800 workplace fatalities annually in the United States alone. This stark statistic underscores the urgent need for grating designs that not only meet functional requirements but also prioritize safety.

Innovative alternatives to serrated steel grating, such as fiberglass reinforced plastic (FRP) grating and aluminum diamond plate, have emerged as effective solutions for enhancing workplace security. FRP grating, for example, offers superior slip resistance while being 70% lighter than steel, significantly reducing the risk of accidents related to heavy lifting. Additionally, studies indicate that aluminum diamond plates provide heightened durability against corrosive environments, thus lowering maintenance costs and potential hazards over time. By adopting these alternative designs, organizations can create safer work environments that align with OSHA standards and ultimately foster a culture of safety.

The quest for heightened safety and durability in industrial settings has sparked a wave of innovation in grating solutions. Traditional serrated steel grating has long been a standard choice, but recent advancements are redefining longevity in this essential infrastructure component. When comparing the lifespan of these new grating solutions, materials such as fiberglass reinforced plastic (FRP) and aluminum alloys are emerging as frontrunners. These alternatives not only resist corrosion but also offer superior strength-to-weight ratios, making them ideal candidates for environments prone to harsh conditions.

In addition to their robust construction, the maintenance requirements of new grating solutions are significantly lower compared to conventional steel options. This reduction in upkeep translates into cost savings over time, as facilities can allocate resources more effectively without the burden of frequent replacements or repairs. Moreover, the enhanced slip resistance and lightweight design of materials like FRP can improve safety for workers navigating these surfaces, further solidifying their necessity in modern applications. As we continue to explore innovative alternatives, it becomes increasingly clear that investing in durable grating solutions will pay dividends in safety and operational efficiency.

When assessing the long-term savings associated with innovative grating options, it is essential to consider the lifecycle costs. According to a report by Allied Market Research, the steel grating market is projected to reach $3.3 billion by 2025, indicating a robust demand for more efficient and cost-effective alternatives. Traditional serrated steel grating, while durable, often incurs significant maintenance costs over time, particularly in harsh environments. In contrast, innovative materials such as fiberglass and composite gratings have shown to provide substantial long-term savings due to their resistance to corrosion and lower weight, which decreases installation expenses.

Additionally, a study from the National Institute of Standards and Technology highlights that advanced grating solutions can reduce safety risks, which is a critical factor in industries such as construction and manufacturing. By integrating grating that minimizes slip and fall hazards, companies not only enhance employee safety but also reduce the likelihood of costly insurance claims. For example, facilities that adopted high-friction composite grating reported a 40% decline in workplace accidents, translating to significant financial savings over time. These innovations are not just about upfront costs; they reflect a strategic investment in overall safety and durability, proving that innovative grating alternatives can lead to substantial economic benefits.

User experience plays a crucial role in evaluating the effectiveness of alternative grating designs. Feedback gathered from users highlights the importance of safety and usability in industrial settings. Many users have reported that innovative materials, such as fiberglass composites or aluminum, not only provide superior grip but also reduce the risk of slips and falls. These alternatives often feature smooth edges and ergonomic designs that enhance foot comfort, making them a preferred choice for prolonged use in busy environments.

When considering alternatives to serrated steel grating, it is essential to keep user feedback in mind. Here are some tips to maximize safety and usability:

Implementing user-centered designs not only promotes safety but also enhances overall satisfaction among workers, contributing to a more efficient and secure work environment.