In the industrial sector, the choice of materials significantly impacts operational efficiency and safety. Among various options, Galvanized Steel Bar Grating stands out due to its remarkable durability and resistance to corrosion, making it an ideal choice for demanding environments. According to a report by the American Institute of Steel Construction, galvanized steel products can last up to 70 years with minimal maintenance, substantially reducing long-term costs. Moreover, the National Association of Steel Producers notes that over 90% of steel produced in the U.S. is either galvanized or coated, underlining its popularity and effectiveness in industrial applications. As industries increasingly prioritize sustainability and longevity, understanding the advantages of Galvanized Steel Bar Grating becomes crucial for decision-makers seeking to optimize their operations and ensure safety across their facilities.

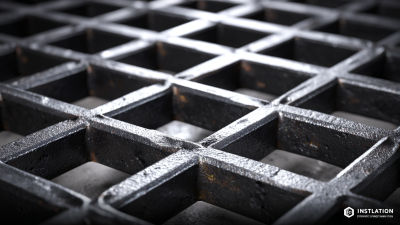

Galvanized steel bar grating is increasingly becoming a preferred choice for many industrial applications due to its distinct advantages. One of the key benefits is its exceptional resistance to corrosion. The galvanizing process, which involves coating the steel with a layer of zinc, protects it from moisture and harsh environmental conditions, making it ideal for outdoor and damp settings. This resilience significantly extends the lifespan of the grating, reducing the need for frequent replacements and maintenance.

Another important advantage of galvanized steel bar grating is its structural strength. With a robust design that can withstand heavy loads, it provides a safe and durable walking or working surface in various industrial environments. This high strength-to-weight ratio not only enhances safety but also allows for easy installation and flexibility in design, catering to different layout requirements. Combined with its low maintenance needs, galvanized steel bar grating proves to be a cost-effective solution for factories, warehouses, and other industrial facilities, ensuring long-term performance and reliability.

| Advantages | Description | Applications |

|---|---|---|

| Corrosion Resistance | Protected by a layer of zinc that prevents rust and extends lifespan. | Chemical plants, wastewater treatment facilities. |

| Durability | Strong and capable of handling heavy loads without deformation. | Heavy machinery platforms, walkways in factories. |

| Lightweight | Easier to transport and install compared to solid steel plates. | Temporary structures, event platforms. |

| Customizable | Available in various sizes and styles to fit specific needs. | Manufacturing plants, commercial installations. |

| Safety Features | Slip-resistant surface provides enhanced safety for workers. | Walkways, stair treads in industrial settings. |

Galvanized steel bar grating has become a popular choice in various industrial applications, thanks to its remarkable durability and longevity. The galvanization process involves coating steel with a protective layer of zinc, which significantly enhances its resistance to corrosion and environmental degradation. This characteristic makes galvanized steel grating particularly suitable for industries exposed to harsh conditions, such as chemical processing or wastewater treatment, where standard materials may quickly deteriorate.

In addition to corrosion resistance, galvanized steel provides superior structural integrity compared to alternatives such as aluminum or plastic. With its higher strength-to-weight ratio, it can support heavier loads and withstand impact better, making it ideal for flooring, walkways, and maintenance platforms. Furthermore, the longevity of galvanized steel means reduced replacement costs and downtime, ensuring that industrial operations can run smoothly without the frequent need for repairs or replacements. Ultimately, the strategic advantages of galvanized steel bar grating position it as a leading choice for industrial applications focused on efficiency and safety.

Galvanized steel bar grating is rapidly gaining traction in various industrial applications, primarily due to its cost-effectiveness alongside durability and versatile utility. The initial investment in galvanized grating may appear higher than alternatives, but when evaluating long-term benefits, it outperforms its counterparts. The corrosion-resistant properties of galvanized steel mean reduced maintenance costs and extended lifespan, ultimately translating into significant savings over time. Maintenance and repair expenses tend to accumulate with less durable materials, making the upfront costs of galvanized options more appealing.

Additionally, the application of advanced technologies, such as vibration-assisted UV nanoimprinting for grating fabrication, suggests an evolving landscape in material efficiency. These innovations can create grating structures with enhanced performance, improving overall functionality in industrial settings. By incorporating robust materials like galvanized steel in applications where high-performance grating is essential, industries can capitalize on the best of both worlds: superior durability and optimized cost-efficiency. This synergy not only boosts productivity but also aligns with modern sustainability goals, promoting a long-lasting resource utilization strategy in the industrial sector.

Galvanized steel bar grating plays a crucial role in enhancing workplace safety across various industrial applications. Its robust construction ensures excellent slip resistance, reducing the chances of workplace accidents. According to the Occupational Safety and Health Administration (OSHA), slips, trips, and falls account for a significant percentage of workplace injuries, making the use of effective safety measures paramount. The open design of steel grating allows for quick drainage of liquids, minimizing the risk of accumulation that can lead to dangerous slip hazards.

To further promote safety, consider these tips: First, regularly inspect the grating for any signs of wear or damage, as even minor deformities can compromise safety. Second, ensure that the grating has appropriate tread patterns, which can enhance grip under various conditions. Finally, it's essential to integrate proper signage around grating areas, especially in locations exposed to moisture, to remind employees to remain vigilant.

The durability of galvanized steel grating also contributes to long-term workplace safety. Its corrosion-resistant properties prolong its lifespan, reducing the likelihood of hazardous failures. As highlighted in a study by the National Safety Council (NSC), implementing high-quality materials not only boosts safety standards but also decreases maintenance costs and downtime, allowing businesses to maintain a safer, more efficient workspace.

Galvanized steel bar grating shines in industrial applications due to its remarkable versatility. Its robust construction and anti-corrosive properties make it an ideal choice for walkways, platforms, and even heavy machinery support systems. In factories and warehouses, galvanized grating can withstand substantial loads while ensuring safe and reliable access to various equipment and areas. Its open design also allows for effective drainage, reducing slip hazards in wet conditions.

**Tips for Choosing Galvanized Steel Bar Grating:**

When selecting galvanized steel bar grating, consider the specific weight load requirements of your application. Ensure that the spacing between the bars aligns with both safety standards and the type of traffic the grating will experience. Additionally, evaluate the surface finish; options range from smooth for pedestrian use to serrated for enhanced traction, perfect for areas exposed to liquids. Regular inspections and maintenance can further prolong the lifespan of your grating, ensuring it continues to provide structural support reliably.

The application range of galvanized steel bar grating extends beyond walkways to include drainage covers and fencing. Its adaptability allows it to be used in various settings, such as commercial buildings, outdoor parks, and manufacturing plants. By incorporating this material, businesses can achieve a combination of safety, efficiency, and longevity in their infrastructures.