In the ever-evolving world of marine construction, the significance of Marine Walking Steel Grating cannot be overstated. As an industry expert, Dr. Emily Chen, a leading material science researcher at Ocean Engineering University, emphasizes, “The durability and safety that Marine Walking Steel Grating provides are essential for the demanding environments of the marine sector.” This innovative material is designed to withstand harsh oceanic conditions while ensuring the safety of personnel and equipment alike.

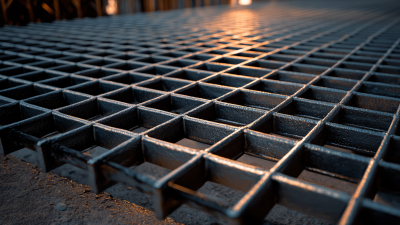

The features of Marine Walking Steel Grating make it an indispensable component in various marine applications, from docks and piers to offshore platforms. Its lightweight yet robust structure allows for easy installation and maintenance, while the grating design ensures effective drainage and reduces slip hazards. With increasing awareness of safety standards in marine projects, the demand for high-quality and reliable grating solutions continues to rise.

Moreover, the benefits of Marine Walking Steel Grating extend beyond safety and durability. It is environmentally friendly, as it can be easily recycled, contributing to sustainable marine practices. This article will explore the top features, benefits, and diverse applications of Marine Walking Steel Grating, highlighting its critical role in shaping the future of marine infrastructure.

In the marine industry, the choice of materials for walkways and decking is crucial for both safety and efficiency. Marine walking steel grating has gained significant popularity due to its innovative features and benefits. One of the standout characteristics of the 2025 edition is its enhanced slip resistance. According to industry reports, grating with a slip-resistant surface can reduce accidents by up to 40%, making it an essential component in high-traffic marine environments.

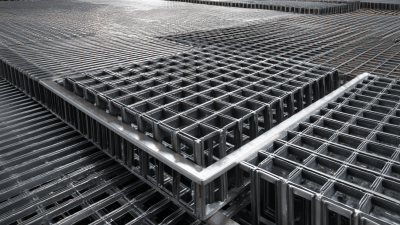

Another noteworthy feature is the lightweight yet robust design of marine walking steel grating. Advances in engineering have allowed for a new generation of gratings that offer superior strength while minimizing weight, which is vital for marine applications. A recent analysis revealed that modern steel gratings can withstand loads of up to 1,500 pounds per square foot, allowing for both operational flexibility and increased safety. Additionally, the corrosion resistance of these products has improved significantly, with coatings that can extend the lifespan of the grating in harsh marine conditions by up to 30% compared to previous generation materials.

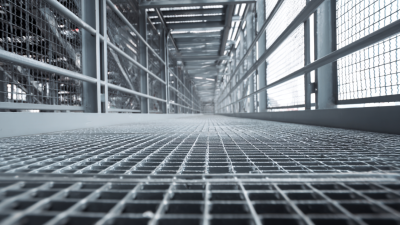

Furthermore, the versatility of marine walking steel grating makes it suitable for varied applications, ranging from shipbuilding to offshore platforms and harbor facilities. The open design not only promotes drainage and reduces ice buildup but also facilitates the passage of light, enhancing visibility in both day and night conditions. With sustainability becoming increasingly important, many manufacturers are now focusing on eco-friendly production practices, which supports a green maritime economy.

Marine walking steel grating offers a multitude of advantages that make it an essential choice for various applications, particularly in environments that require durability and safety. One of the primary benefits is its exceptional strength-to-weight ratio, which allows for easy installation without compromising structural integrity. This type of grating is designed to withstand harsh marine conditions, including exposure to salt water, heavy loads, and constant foot traffic. Its open design promotes drainage and prevents the accumulation of water, reducing slip hazards and enhancing safety for personnel.

Tips: When selecting marine walking steel grating, consider the spacing between bearing bars, as tighter spacing can provide more slip resistance and support for smaller footwear. Regular maintenance, including checking for rust or corrosion, can prolong the life of the grating and ensure it remains safe for use.

Another significant advantage of marine walking steel grating is its versatility. It can be used in a variety of applications, such as walkways, platforms, and ladders on ships, docks, and offshore structures. The customization options available, including different sizes and coatings, make it suitable for specific project needs. Moreover, the durability of steel grating means that it can endure the rigors of marine environments while requiring minimal maintenance, resulting in cost savings over time.

Tips: Always ensure that the grating is compatible with your specific operational environment. Consulting with industry professionals can provide valuable insights into the best practices for installation and long-term maintenance.

Marine walking steel grating is an essential component in various industries, particularly where safety and durability are paramount. Its applications span across shipbuilding, offshore platforms, and fish farming, largely due to its non-slip surface and resistance to corrosive environments. In shipbuilding, for instance, grating provides safe and secure walkways for crew members, ensuring efficiency during operations and maintenance. Offshore platforms utilize grating for catwalks and access areas, where exposure to harsh weather demands materials that can withstand significant wear and tear.

In addition, marine walking steel grating plays a vital role in the aquaculture industry. By allowing water to flow freely around and through the grating, it enhances oxygenation for fish and other aquatic life, contributing to healthier ecosystems. Its easy-to-clean surface reduces algae buildup and maintains vigorous growth conditions, making it a preferred choice for fish farms worldwide.

**Tip:** When selecting marine walking steel grating, consider the load capacity and material grade to ensure it meets the specific demands of your application. Regular inspections and maintenance can prolong the lifespan of grating installations, enhancing safety and reliability in your operations.

When evaluating flooring options for marine environments, marine walking steel grating stands out due to its unique composition and design. Unlike traditional flooring materials such as wood or composite alternatives, marine walking steel grating offers enhanced durability and resistance to corrosion. The open design allows for superior drainage and airflow, reducing the risk of slips and falls, which is especially critical in wet marine conditions. The non-slip surface of steel grating also considerably minimizes accidents, making it a safer choice for high-traffic areas on vessels and docks.

In contrast, alternative flooring materials often require more maintenance and may not withstand harsh marine elements as effectively. For instance, wood may deteriorate over time, leading to splintering and instability, while plastic composites could become brittle under prolonged exposure to UV light and saltwater. Additionally, marine walking steel grating can support heavy loads, which is essential for operations in marine industries. Overall, the comparative longevity, safety features, and low maintenance of marine walking steel grating make it a leading option over other flooring choices in challenging marine environments.

To ensure the longevity of marine walking steel grating, proper maintenance is essential. Regular inspections should be conducted to identify any signs of corrosion or wear. Given the corrosive nature of marine environments, it is crucial to check for rust and other forms of degradation frequently. If any issues are found, immediate action should be taken to address them, such as cleaning the affected areas and applying protective coatings to prevent further deterioration.

Cleaning is another vital aspect of maintenance. The grating surfaces should be cleared of debris and marine growth, which can hold moisture and lead to corrosion over time. Utilizing brushes or pressure washers can effectively remove stubborn materials. Additionally, applying anti-slip treatments contributes not only to safety but also aids in preserving the grating's surface by reducing the chances of damage during foot traffic. Regular maintenance routines that include cleaning, inspection, and prompt repairs will significantly enhance the lifespan and functionality of marine walking steel grating, ensuring it remains safe and effective for its intended applications.