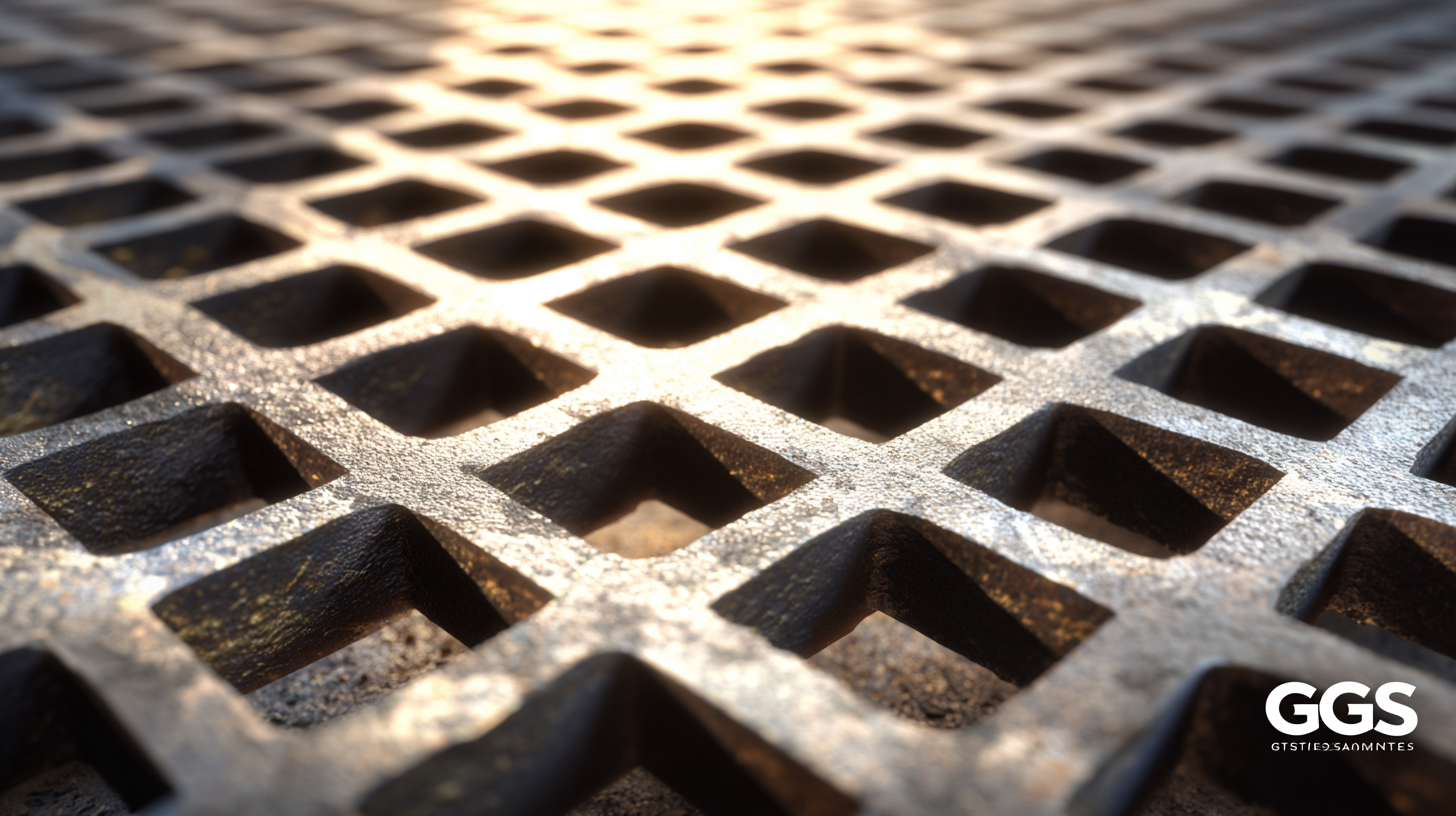

As we look ahead to 2025, understanding the emerging technology trends is crucial for optimizing industrial operations and enhancing safety and efficiency. One area that is gaining significant attention is the use of Serrated Steel Grating. Known for its superior slip resistance, durability, and low maintenance requirements, serrated steel grating solutions are rapidly becoming a preferred choice across various industries. This blog will delve into the numerous benefits of implementing serrated steel grating, highlighting its applications in environments where safety is paramount. From construction sites to commercial facilities, the characteristics of serrated steel grating not only meet industry standards but also provide long-lasting solutions that improve operational performance. Join us as we explore the best serrated steel grating solutions available, ensuring you stay informed and equipped for the technological advancements that lie ahead.

As we approach 2025, the landscape of serrated steel grating design is set to undergo significant innovations, driven by advancements in materials and manufacturing processes. Emerging technologies such as enhanced welding techniques and the use of high-strength coatings are improving the durability and performance of these gratings, making them more effective for a variety of applications, including industrial floors and pedestrian walkways.

Tip: When considering serrated steel grating solutions, look for products that incorporate anti-slip features and corrosion-resistant materials. This not only ensures safety but also increases the longevity of the installation, making it a cost-effective choice in the long run.

Furthermore, the steel grating market is expected to experience growth across various regions, with increasing investments in infrastructure development. Companies that leverage innovative design techniques will likely gain a competitive edge. The focus on sustainability is also leading to the use of recycled materials in manufacturing, aligning with global efforts towards greener construction practices.

Tip: Always request samples and performance data to evaluate the quality and effectiveness of any serrated steel grating option. This proactive approach will help you make informed decisions that meet your project's specific requirements.

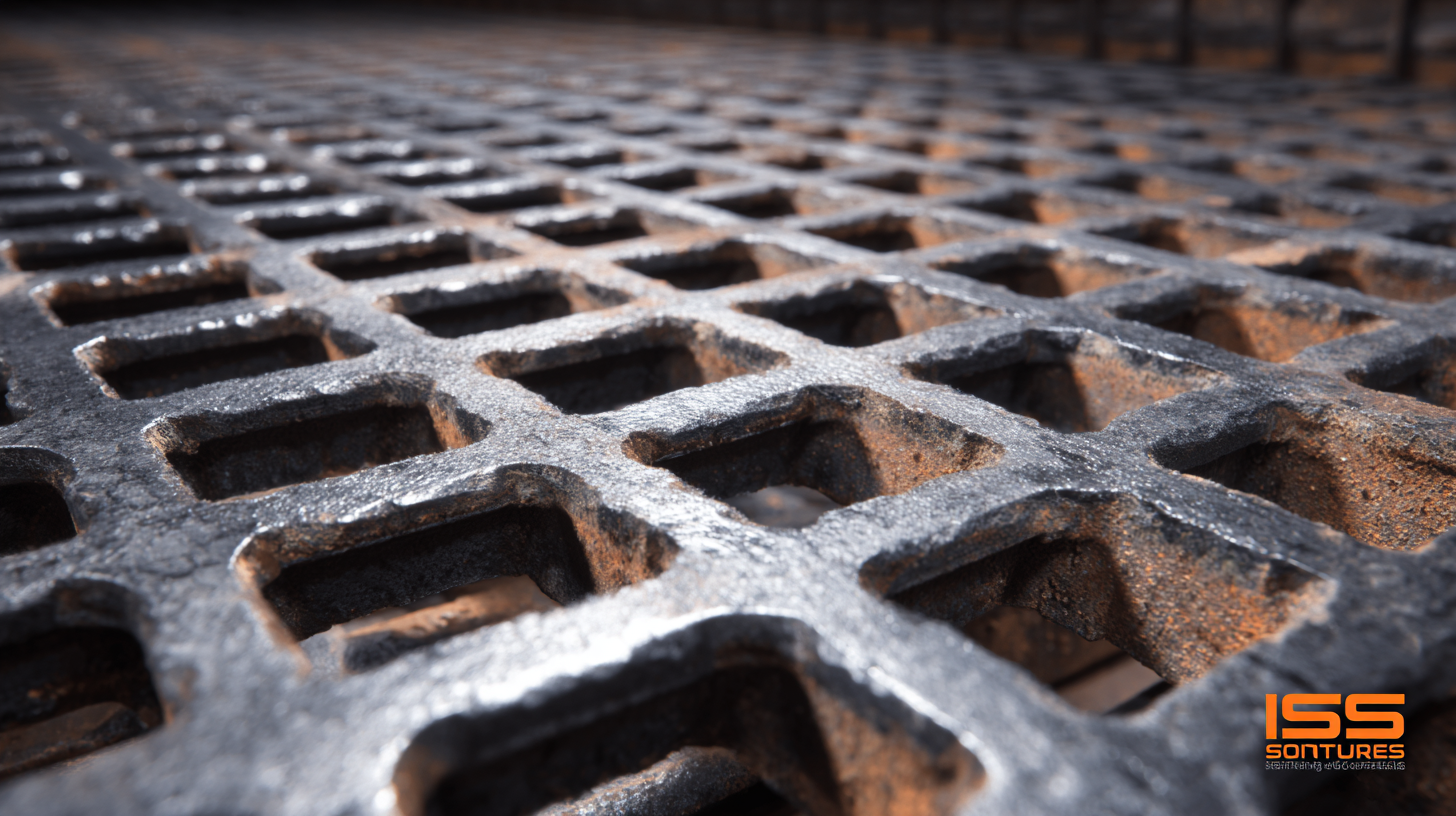

When it comes to selecting the best serrated steel grating solutions, understanding the impact of material composition on performance is crucial. The choice of steel grade and the presence of elements like manganese, carbon, and chromium can significantly affect the durability, corrosion resistance, and load-bearing capability of the grating. High-quality serrated steel grating often utilizes alloyed stainless steel, which not only enhances the strength but also provides a longer lifespan, making it ideal for demanding environments.

Tip: Always consult with manufacturers to understand the specific material compositions they offer. This knowledge can help you choose a grating solution that meets your project's specific needs, ensuring safety and efficacy. Additionally, consider the environmental conditions the grating will face; for instance, galvanization can enhance the lifespan of steel grating in outdoor applications.

Incorporating the right material composition is not just about durability; it's also about optimizing performance under various load conditions. Serrated edges improve slip resistance, making grating solutions safer for foot traffic and equipment. This innovative design works in tandem with high-quality materials to provide reliable and secure solutions in industrial settings.

Tip: Regular maintenance and inspection of your serrated steel grating can identify wear and corrosion early, allowing for timely interventions that extend its usable life and maintain safety standards.

The demand for serrated steel grating in infrastructure projects is witnessing significant growth, driven by the need for durable and slip-resistant surfaces in various applications. According to a recent report by Grand View Research, the global steel grating market is expected to reach USD 3 billion by 2025, with a compound annual growth rate (CAGR) of approximately 4.8%. This surge is largely attributed to the expanding construction industry and increasing investments in urban infrastructure, where serrated steel grating provides both safety and efficiency.

The demand for serrated steel grating in infrastructure projects is witnessing significant growth, driven by the need for durable and slip-resistant surfaces in various applications. According to a recent report by Grand View Research, the global steel grating market is expected to reach USD 3 billion by 2025, with a compound annual growth rate (CAGR) of approximately 4.8%. This surge is largely attributed to the expanding construction industry and increasing investments in urban infrastructure, where serrated steel grating provides both safety and efficiency.

Infrastructure projects, particularly in transportation and industrial sectors, are increasingly incorporating serrated steel grating solutions due to their superior performance characteristics. For instance, the Federal Highway Administration approximately allocates $160 billion annually for highway infrastructure, part of which is directed towards materials that enhance pedestrian safety and structural integrity. The slotted design of serrated grating not only improves drainage but also reduces the risk of slips and falls in critical areas, making them an essential component in modern infrastructure development. As cities continue to grow and evolve, the focus on sustainable and resilient materials like serrated steel grating will undoubtedly play a pivotal role in shaping the future of construction and safety standards.

Serrated steel grating has emerged as a crucial component in various industrial applications, particularly as we progress towards 2025. One of the primary uses of serrated steel grating is in walkways and platforms, where safety is paramount. The unique design of the serrated edges enhances traction, reducing the risk of slips and falls in high-traffic areas. This feature makes it an ideal choice for industries such as construction, manufacturing, and even in commercial settings.

Serrated steel grating has emerged as a crucial component in various industrial applications, particularly as we progress towards 2025. One of the primary uses of serrated steel grating is in walkways and platforms, where safety is paramount. The unique design of the serrated edges enhances traction, reducing the risk of slips and falls in high-traffic areas. This feature makes it an ideal choice for industries such as construction, manufacturing, and even in commercial settings.

Another significant application of serrated steel grating is in heavy-duty equipment access. The robust construction and lightweight nature of the grating allow for easy installation on machinery and equipment, providing reliable access while ensuring safety. Additionally, these gratings are highly resistant to corrosion and harsh chemicals, making them suitable for environments like wastewater treatment plants and chemical processing facilities. As industries increasingly prioritize safety and efficiency by 2025, serrated steel grating will undoubtedly remain a vital solution in the industrial landscape.

As the world increasingly prioritizes sustainability, steel grating solutions are evolving to meet these eco-friendly demands. Innovations in production processes are significantly reducing carbon footprints, utilizing recycled materials, and optimizing energy consumption. Companies are now investing in technologies that allow for the recycling of old steel grating, transforming waste into valuable resources. This circular economy approach not only prevents landfill overflow but also fosters a sustainable lifecycle for construction materials.

Moreover, advancements in sustainable design are making steel grating applications more versatile and efficient. Manufacturers are exploring the integration of biodegradable coatings and treatments that enhance durability while minimizing environmental impact. These efforts align with green building certifications and guidelines, supporting architects and builders seeking to construct environmentally responsible projects. By embracing these eco-friendly trends, the steel grating industry is not just keeping pace with contemporary sustainability practices but is also setting a precedent for future developments in technology and manufacturing.